Introduction

There are many different machining processes used in industries but nowadays the Non-conventional machining processes are taking dominance over the conventional ones due to their better suitability in complex manufacturing, precision and ease of use. Ultrasonic machining is one of the top Non-traditional machining process. It has become very popular in the present time due to its ability to machine hard surfaces.

Mechanism of Ultrasonic Machining

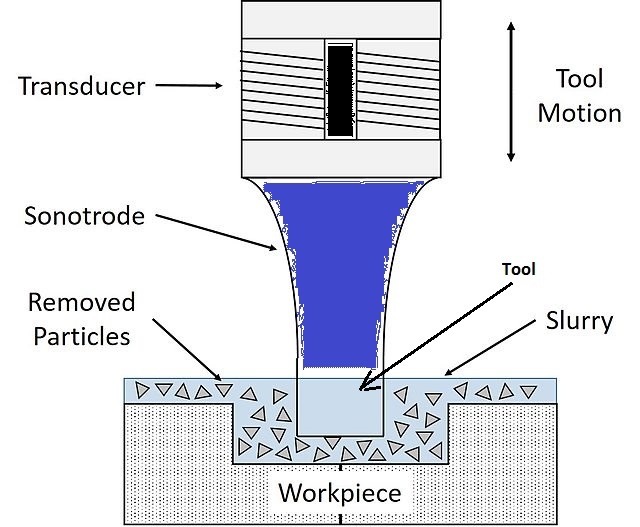

Ultrasonic machining is a subtraction manufacturing process that removes material from the surface of a specimen through high frequency, low amplitude vibrations of a tool against the material surface in the presence of fine abrasive parties. The tool travels vertically to the surface of the part at amplitudes of 0.05 to 0.125 mm. The fine abrasive grains are mixed with water to form a slurry that is distributed across the part and the tip of the tool. Typical grain sizes of the abrasive material range from 100 to 1000, where smaller grains produce smoother surface finishes. Ultrasonic machining is typically used on brittle materials as well as materials with a high hardness due to micro-cracking mechanics.

Components of Ultrasonic Machining

(i) Abrasive slurry (slurry means a paste like substance)

(ii) Tool

(iii) Circulating pump

(iv) Ultrasonic transducer

(v) Work piece

(vi) Ultrasonic oscillator

(vii) Reservoir and

(viii) Tool holder.

Principle of Ultrasonic Machining

The “slurry” is composed of very small abrasive particles. This slurry is forced against the work piece by a vibrating tool. This removes the work piece material in the form of very small chips. The abrasive grains used to make the slurry are made of silicon carbide, aluminum oxide, boron carbide or diamond dust.

In this process of Ultrasonic Machining, a “Transducer” is used to produce high frequency longitudinal vibrations which is 20 KHz to 30 KHz with amplitude between 0.01 mm to 0.06 mm. The term “ultrasonic” is used to describe vibratory wave of frequency above that of the upper frequency limit of human ear which is 20 KHz (ie., 20000 Hz).

Ultrasonic Machining (USM) employs a distinct mechanism to remove material from a workpiece, which plays a critical role in its effectiveness. At its core, USM utilizes a tool that vibrates ultrasonically in close proximity to the workpiece, with typically a 0.25 mm gap maintained between them. This gap is filled with a slurry containing abrasive particles.

The removal of material is facilitated through the repetitive hammering action of the abrasives, driven by the downward motion of the ultrasonically vibrating tool. Each vibration causes the abrasives to impact the surface of the workpiece, mechanically eroding and removing material particle by particle. This action is critical because it allows for precision milling of hard materials without generating excessive heat or requiring significant force.

Furthermore, the slurry plays a dual role by not only suspending the abrasive particles but also by assisting in the removal of the eroded material from the work zone. This prevents any build-up of debris, which could interfere with the machining process. The flushing of the debris ensures that the cutting process remains efficient and clean, enabling more precise and accurate machining.

Such operational dynamics of USM make it an effective method for creating intricate and precise shapes in hard materials, with controlled removal of material through a carefully regulated mechanical process. The efficiency of this method is further enhanced by adjusting various parameters, such as vibration frequency and amplitude, and the composition and viscosity of the slurry, which directly influence the rate and quality of material removed.

In comparing material removal rates among different machining processes, Ultrasonic Machining (USM) exhibits a performance that is intermediate between Electrochemical Machining (ECM) and Electrical Discharge Machining (EDM). Specifically, the material removal rate in USM is typically lower than that of ECM, which is known for its higher efficiency, but exceeds the removal rate seen in EDM. This positioning is due to the distinct mechanisms employed by each technology in removing material from the workpiece.

The transducer works on the principle of “magnetosriction” where the material changes in dimension when subjected to alternating magnetic field. These changes in dimension appear as vibration of the transducer. In Ultrasonic Machining, the tool is pressed on to the work surface with a light pressure. The abrasive slurry which is a mixture of abrasive grains and water, is made to flow under pressure through the interface of the tool and the work piece. Under the impact of the tool, the abrasive particles perform metal removing operation. In this way, the tool impresses its image on the job. The tool used for USM is made of stainless steel.

Application of Ultrasonic Machining

(i) Making round holes or holes of any shape

(ii) Performing machining operations like drilling, grinding, milling etc.

(iii) Machining very hard materials like tungsten carbide, ceramics, glass, gem, etc.

(iv) Cutting threads on components made of very hard material

(v) Making wire drawing dies made of tungsten carbide or diamond.

(vi) Helping a dentist to drill painless hole in the teeth of the patient.

Advantages of Ultrasonic Machining

i) Ultrasonic Machining is used for machining extremely hard and brittle materials to complex shapes with good accuracy and reasonable surface finish.

ii) It is not affected by the electrical or chemical characteristics of the work materials.

iii) Holes of any shape can be produced.

iv) Machined work piece is free of stress

v) Operation is noiseless and safe

vi) Due to very less heat generation, physical properties of the work piece remain unaffected.

Conclusion

Ultrasonic Machining is a Non-Traditional Machining process which is best suited to remove material or perform machining operation of hard and brittle specimens by using a slurry of abrasive grains.

Another machining operation that uses abrasive particles to remove material is Grinding. Read more about it.

1. How does Ultrasonic Machining maintain precision and efficiency in shaping materials?

In Ultrasonic Machining (USM), precision and efficiency are achieved by applying high-frequency ultrasonic vibrations, usually between 20,000 and 50,000 Hz. This technique is particularly effective for processing hard and brittle materials, as the vibrations facilitate precise material removal with minimal waste and damage to the workpiece.

2. How does material removal occur in Electrical Discharge Machining (EDM)?

In EDM, the removal of material is achieved through the use of controlled electrical discharges that occur between the tool and the workpiece.

3. How does material removal occur in Ultrasonic Machining (USM)?

In USM, the material is removed by the action of abrasive particles that are propelled against the surface of the material using high-frequency vibrations.

4. Does Ultrasonic Machining introduce any thermal damage or residual stress to the workpiece?

No, the process is beneficial as it does not cause thermal damage or induce residual stress in the material being machined.

5. Can Ultrasonic Machining create intricate and complex shapes?

Yes, Ultrasonic Machining allows for the creation of complex and detailed 3D shapes with high precision.

6. How do various parameters such as frequency, amplitude, abrasive concentration, and size affect the material removal rate in Ultrasonic Machining?

Various parameters such as frequency, amplitude, abrasive concentration, and size play crucial roles in affecting the material removal rate in Ultrasonic Machining. The process involves high-frequency vibrations ranging from 20 KHz to 30 KHz with amplitudes between 0.01 mm to 0.06 mm. Specifically, elevating the frequency results in increased material removal rate as more impacts occur per unit time, enhancing the efficiency of the machining process. Similarly, increasing the amplitude not only allows for a greater range of motion but also enhances the momentum of the abrasives, thereby boosting the material removal rate. The abrasive slurry, composed of small abrasive particles like silicon carbide or diamond dust, is forced against the workpiece by a vibrating tool to remove material in the form of small chips.

Adjusting the concentration of these abrasives plays a critical role; a higher abrasive concentration leads to more impacts and increases the material removal rate until a point where collisions between the abrasive particles cause momentum loss, subsequently reducing the efficiency. The size of abrasive grains in the slurry ranges from 100 to 1000, with smaller grains producing smoother surface finishes. Increasing the size of the abrasive results in a larger impact area, which boosts the material removal rate initially. However, exceeding a certain size diminishes the momentum of the abrasives, thus affecting the rate negatively.

Additionally, the tool is pressed onto the work surface with light pressure, allowing the abrasive particles to perform the metal removal operation. Therefore, adjusting these parameters can significantly impact the material removal rate and the overall efficiency of Ultrasonic Machining. Through careful manipulation of frequency, amplitude, abrasive concentration, and abrasive size, the material removal rate can be optimized to achieve desired machining outcomes.<