A number of foundry tools and other equipment are used in foundry work, particularly in sand moulding for doing different kind of foundry operation. All of them are classified as below

HAND TOOLS

The common hand tools in foundry work as following

1. SHOVEL-

It is an iron Pan fitted with a wooden or metal handle. It is used in mixing and conditioning the sand manually and transferring it to the flask.

2. HAND RIDDLE-

it consists of a wooden frame fitted with a standard wire mesh fitted at the bottom side, used for sorting out sand from the foreign particles like stones, etc.

3. RAMMERS-

Rammers are used for striking the sand mass in the moulding box to pack it uniformly around the pattern. The common forms of rammers used in hand hammering are following:

A. Peen Rammer- It is a wedge shaped construction formed at bottom of metallic rod. It is a common hand tool and is quite useful in packing the sand in packets and corners.

B. Hand rammer- It is smaller than former and generally made of wood or metal and one side is wedge shaped called peen on other end is solid cylindrical shape.

C. Floor rammer- It consist of a long Steel bar carrying a peen at one end and flat part on the other. It is larger and heavier tool than all the above.

4. STRIKE OF BAR

It is a flat bar made of wood or iron to strike at the axis and from the top of a box after ramming. One of its edge is made beveled and opposite side surface is made perfectly smooth and plane.

5. VENT WIRE-

It is a thin Steel rod or wire carrying a pointed edge at one end and a wooden handle on the opposite side or a bent look at the other after ramming and striking of excess sand, it is used to make small holes called Vents through sand mould to allow the exit of gases and steam during casting.

6. TROWELS-

Trowels are used for finishing flat surfaces and joints in mould. The common shapes of trowels are flat iron Pan attached with a wooden handle.

7. SLICKS-

They are used for repairing and finishing the mould surfaces and edges after the pattern has been withdrawn. The commonly used slicks are heart, leaf, square, spoon and bead shaped.

8. LIFTERS/ CLEANERS-

It’s a finishing tools used for repairing and finishing the sand mould after withdrawal of pattern. They are also used for removing loose sand from mould cavity.

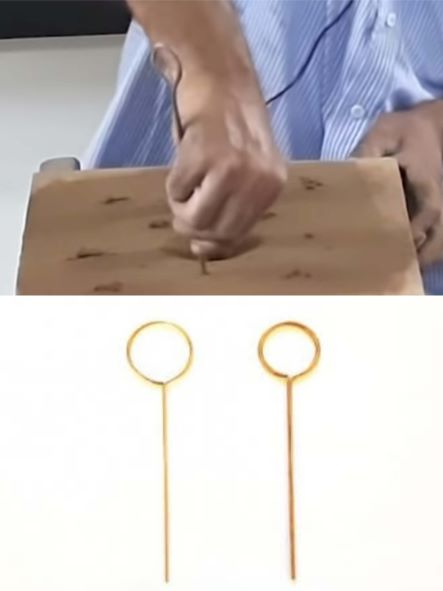

9. DRAW SPIKE-

It’s a tapered steel rod having a Loop or ring at it’s one end and other end is shaped. It’s used to rap and draw patterns from mould.

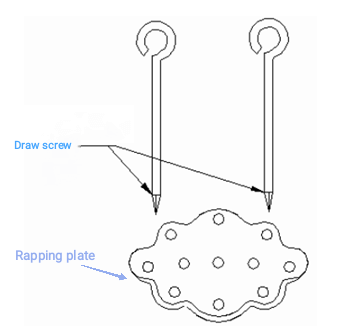

10. DRAW SCREW AND RAPPING PLATE-

Draw screws is a straight mild steel rod carrying a Loop at one end and other end is screw thread. They are used with a rapping plate for rapping and pulling out the pattern from the mould.

11. MALLET-

it is similar to hammer just made of wood used in carpentry workshop. In foundry work it’s used to drive draw spike in the pattern and then rapping it.

12. Swab-

Its a hemp fiber brush used for moistening the edges of sand mould which are in contact with the pattern surface. Before withdrawing the pattern it is also used for coating liquid blanking on the mould faces in dry sand mould.

13. CLAMP COTTER AND WEDGE-

It is made of steel and are used for clamping the moulding boxes firmly together during pouring.

14. GAGGERS-

It is a bent piece of wires and rods which are used for reinforcing the downward projecting boxes sand mass in the cope are known as gaggers.

15. BELLOW-

A hand operated bellow is used to blow away the loose or unwanted sand from the surface and cavity of mould.

16. NAILS AND WIRE PIECES-

They are used to reinforce thin projections of sand in the mould or cores made in two halves.

READ ALSO- Top 5 material used for making pattern & It’s properties.

CONTAINERS-

The Common containers used in foundry work are the following:-

A. Moulding boxes or flask

B. Ladles

C. Crucible

17. MOULDING BOXES OR FLASKS-

In foundry workshop 2 types of moulding boxes used-

A. CLOSED MOULDING BOXES

B. OPEN MOULDING BOXES or SNAP Type

Its made of wood,cast iron or steel. It has generally two parts- 1. Upper parts- COPE & 2. Lower parts- DRAG.

Sometimes it has a middle part also, called cheek. All parts are aligned carefully after withdrawal of pattern and then clamped together for pouring operation. Remember wooden flasks generally used for green sand and metal flask used for dry sand due to it’s high heat producing capabilities.

18. LADLES-

It’s used to transfer molten metal from furnace to Moulding boxes. It has a outer structure made of steel and Refractory lining inside. Depending on size of casting, different size of ladles are used that is, from 50 kg to 30 tons. If slag is less, metal is poured from upper openings, else bottom pour ladle is used.

REFERRENCES:-

A. Manufacturing Technology by P.N Rao

B. Image source- https://www.indiamart.com/