Table of Contents

- Definition of Electrode

- Welding Electrode selection chart

- Welding Electrodes Types

- Types and composition of flux coating

- Purpose of Flux coating

- Low Hydrogen electrode

Definition of Electrode:-

An electrode is a metallic wire of standard size and length generally coated with flux( maybe bare) used to complete the welding circuit and to provide filler material to the joint by an Arc maintained between its tip and the work.

Welding Electrode selection chart with amperage in different countries:-

| Indian(mm) | British(S.W.G) | American(inch) | Current(Ampere) | Length(mm) |

| 1.6 | 16 | 1/16″ | 25-40 | 250 |

| 2.0 | 14 | 5/64″ | 40-60 | 300 |

| 2.5 | 12 | 3/32″ | 60-90 | 350 |

| 3.15 | 10 | 1/8″ | 90-130 | 350 |

| 4.0 | 8 | 5/32″ | 140-190 | 450 |

| 5.0 | 6 | 3/16″ | 180-240 | 450 |

| 6.3 | 4 | 7/32″ | 230-310 | 450 |

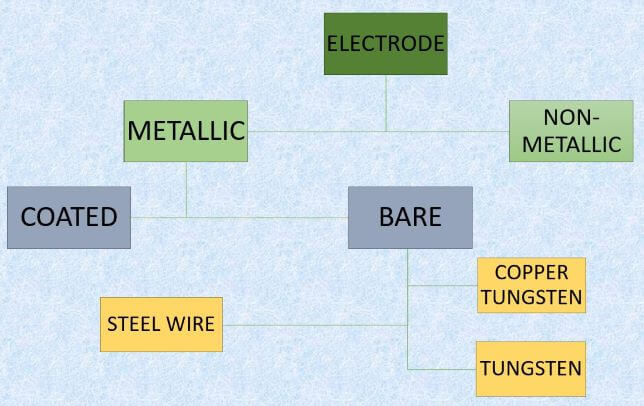

Welding Electrodes Types:-

Classification of MMAW electrode:-

Electrodes are classified depending upon the following factors.

- Method of coating,

- Coating factor,

- Type of flux,

- Purpose of flux coating,

- Cold wire material.

Coating factor:-

Coating factor= OUTSIDE DIA OF ELECTRODE/ INSIDE DIA OF ELECTRODE.

| COATING FACTOR | TYPES OF ELECTRODE |

| 1.25-1.253 | Light Coated |

| 1.40-1.5 | Medium Coated |

| 1.60-2.20 | Heavy Coated |

Type of flux coating:-

- Cellulose coated electrode,

- Rutile coated electrode,

- Iron oxide coated electrode,

- Basic coated electrode.

Composition of flux coating:- The coating of the welding electrodes consists of a mixture of the following substances are

1. Oxidizing substances:-

The Oxidising substances make the weld metal flow freely.Some oxidizing substances are:-

- Iron oxide,

- Laminate,

- Magnetite.

2. Reducing substances:-

This substances compensate for the burning of Manganese, Ferro silicon.Some Reducing substances are:-

- Ferro-manganese,

- Ferro-silicon,

- Ferro-titanium.

3. Ionizing substances:-

These are carbonates known as chalk and marble. These are used for stabilization of the arc.

4. Organic substances:-

These substances from gases which aid the transfer of metal. They also Shield the welding arc and weld pool. Some Organic substances are:-

- Wood,

- Flour dextrine,

- Cellulose.

5. Bending and plasticizing substances:-

These substances help the applied coating to grip firmly around the core wire of the electrode.Some Bending and plasticizing substances are:-

- Sodium silicate,

- Potassium silicate.

Purpose of flux coating:-

- Its stabilize the arc by ionizing the air.

- It forms a gaseous shield around arc which protects the molten pool and weld pool from atmospheric contamination.

- It compensates the losses of certain elements which are burnt out during welding.

- It slow down the rate of cooling of deposited metal by covering with slag and improves it’s mechanical properties.

- It helps to give good appearance and penetration to the weld.

- It makes the welding easy.

- It acts as a cleaning agent to dissolve oxides and the material for welding.

Low Hydrogen electrode:-

These electrode are called basic coated electrode. They have super heavy coating of flux. The coating contains the lime compounds i.e. fluoride and calcium carbonate. They are connected with positive side of D.C Welding. Function of low Hydrogen electrode are following,

- The arc gives less heat.

- Molten pool solidifies quickly.

- Very good quality weld can be achieved.

- Thick and high speed steel (H.S.S) can be welded successfully.

- It protects the weld bead from cracking.

- It reduces diffusible hydrogen.