Have you ever wondered which is the most commonly used welding type in the industries? This has always been a question for everyone interested in manufacturing of fabricated components. Read on to find out.

We know that when it comes to metal fabrication or joining, welding is one of the most preferred methods. But among welding there are various types such as Spot welding, Submerged Arc welding, Manual metal arc welding and many more, each one having their specific applications.

But, can you say which is the most commonly used welding method across various industries? Most probably, you guessed it right. Most commonly used welding method is MIG welding.

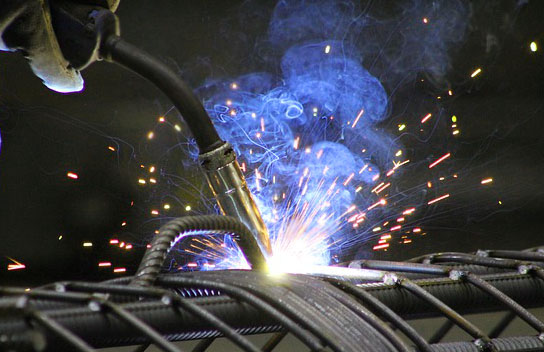

MIG welding or Metal Inert Gas welding, also commonly known as GMAW welding or Gas Metal Arc Welding is one of the most commonly used type of welding across various industries.

Wherever there is a requirement of continuous long welds, which is generally the case in many industries, MIG welding is the most preferred one. It has its own advantages and obvious reasons to qualify as the most preferred welding method. Gas welding or oxy-acetylene gas welding would also give it a tough fight which is another very commonly used welding method that we see in day to day lives.

Some of the features and advantages which makes MIG welding the most preferred welding method are:

I. Continuous supply of filler material (electrode).

Unlike Manual Metal Arc Welding, you don’t have to change the electrodes again and again. Electrode itself serves as the filler material and is continuously supplied in the form of coiled wire. This also makes the process smoother and faster.

II. Easy for the welder

MIG welding is easy for the welder as the distance between the welding gun and work piece doesn’t need to be adjusted again and again as the supply of filler material is automatic and continuous.

III. Compatible with various materials

MIG welding can be suitably used for welding a lot of different materials such as various steel and aluminum alloys , copper alloys and magnesium alloys.

IV. No slag formation

In MIG welding, generally Carbon dioxide is used as the shielding gas (inert gas) which protects the weld from oxidation but it doesn’t form any slag on the weld. Thus chipping time and effort to remove slag is saved.

Apart from these advantages, MIG or GMAW welding also gives a high deposition rate with good penetration and overall better quality of weld. It is also suitable for welding thinner sections.

Edge preparation of parent material is also not required in most cases and thus it saves a lot of time and therefore it is one of the most preferred welding method in the shop floor of industries for general purposes.