what is up milling and down milling

Before understanding differrences between Up milling and down milling, let’s see what is milling operation. Milling operation is a cutting process where rotary cutter(Multi-point tool) is used to remove material from work piece to create flat or Complex shapes in perpendicular direction to its axis of rotation. During whole operation job piece is fixed rigidly in Jig and fixture There are mainly Two process of cutting materials from workpiece through milling machine i.e.

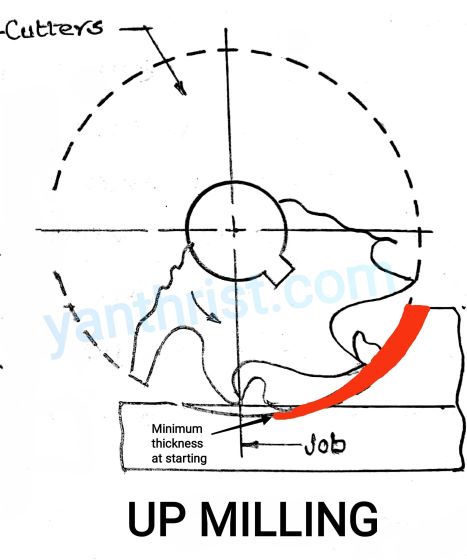

1. UP Milling/Conventional Milling- Here cutter rotates opposite direction of job piece movement.

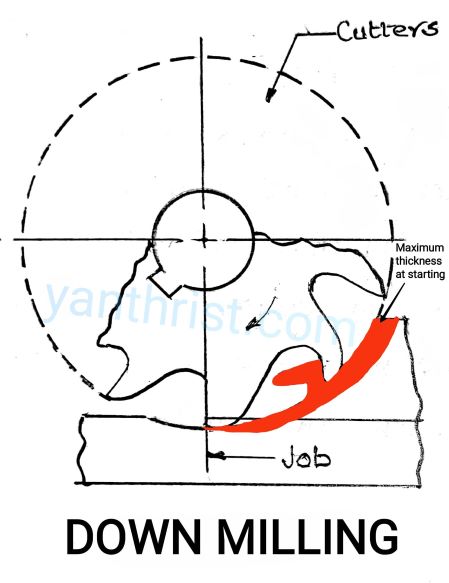

2. Down Milling/ Climb Milling- Here cutter rotates in same direction of work piece being fed.

DIFFERENCE BETWEEN UP MILLING AND DOWN MILLING

| Points | UP MILLING | DOWN MILLING |

| 1. | Cutter rotates against the direction of job being fed. | Cutter rotates in same direction of job being fed. |

| 2. Chip thickness | Chip thickness is zero at initial and increases to maximum at end of feed. | Chip thickness is maximum at starting and decreases to zero at end of feed. |

| 3. Tool wear | Tool wear is more as it rotates against feed. | Tool wear is less comparatively as cutter rotates in same direction of job. |

| 4. Alternative name | It also called Conventional Milling. | It also called Climb Milling. |

| 5. Cutting force | It varies from zero to maximum. | It varies from maximum to zero. |

| 6. Rigidity | Less rigid as cutter tends to lift job. | More rigid as cutter pressing job downwards. |

| 7. Job property | Here heat diffuse into job that changes work-piece property. | Here most of heat shared by chip that doesn’t change workpiece property. |

| 8. Cutting chips stored | Chips fall down infront of cutting tool and cuts again causes less surface finish. | Chips stored behind the tool gives better surface finish. |

| 9. Jig and fixture | Due to lifting tendency high strength jig and fixture required. | Due to downward pressing force, Normal Jig and fixture can be used. |

| 10. Use of Cutting fluid | Difficult to use. | Easy to use. |

| 11. Tool life | Tool life is low. | Tool life is comparatively high. |

| 12. Surface finish | Surface Finish is good. | May be better if backlash error can be avoided. |

| 13. Application | Up Milling used for machining forging and casting job. | Down milling used for slot cutting, grooving, keyway cutting etc. |

| 14. Work-piece material | Bronze, brass and most of ferrous metal cut by Up milling. | Alluminium and it’s alloys cut by Down milling. |

| 15. Diagram |  |  |