MIG and TIG Welding are one of the most commonly known welding method. In this article we find out some key differences between them.

DIFFERENCE BETWEEN MIG AND TIG WELDING:-

| MIG WELDING | TIG WELDING |

| 1. it’s Full form- METAL INERT GAS WELDING. | 1. it’s Full form- TUNGSTEN INERT GAS WELDING. |

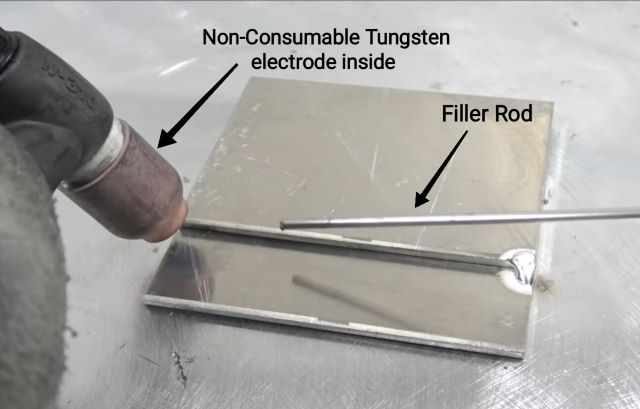

| 2. MIG welding uses consumable electrode that is bare or naked type. | 2. TIG welding utilizes non-consumable electrode. |

| 3. Electrode material steel, aluminum, copper, brass, bronze. | 3. Tungsten is used as electrode material; and to prevent its melting Zirconium, Thorium is added. |

| 4. Shielding gas used i.e. pure Ar, Ar + Co2 mixture, Helium, Co2 . | 4. Shielding gas used i.e. pure Argon(Ar). For copper welding Nitrogen gas used. |

| 5. Shielding gas mixes with welding area. | 5. Shielding gas is used to protect welding area from atmospheric contamination. |

| 6. Continuous feeding of electrode roll is done which acts as filler material. | 6. Filler material is used separately as a rod. |

| 7. DC Reverse polarity used to get a stable arc between metal(-ve i.e. cathode) and electrode(+ve i.e. anode) | 7. Both AC & DC power used. AC for aluminum, magnesium. DC reverse polarity is less used. Note DC Straight polarity high heat generated but arc is unstable. |

| 8. It’s fast process. | 8. it’s comparatively slow process. |

| 9. It can weld metal upto 40 mm thickness. | 9. It can weld metal upto maximum 6 mm thickness. |

| 10. Metal like silicon, carbon, Low alloys steel, magnesium, copper can be easily weld. | 10. Metal like aluminium, magnesium, nickel, Inconel, High temperature and high stress absorbing surface like titanium, Zincronium can be welded. |

|  |

To know about MIG welding in details, please go through our other article:- This is the most commonly used welding in industries.