A venturimeter is a device used for measuring the flow rate of fluids in pipes. It is based on the principle of Bernoulli’s equation, which relates the velocity and pressure of a fluid. The venturi meter is designed to create a pressure difference as the fluid flows through it, allowing for accurate flow measurement. Its primary purpose is to provide reliable and precise data on fluid flow rates, making it an essential tool in various industries and applications.

Venturimeter plays a crucial role in fluid flow measurement for several reasons. Firstly, they offer high accuracy in determining flow rates, providing valuable data for process control, optimization, and analysis. By accurately measuring the flow, venturimeter helps ensure efficient operation and prevent wastage or inefficiencies in fluid-based systems.

Table of Contents

Specifications of Venturimeter

The specifications of venturimeters can vary depending on the specific application and design. However, some common data and dimensions associated with venturimeters include:

1. Inlet Diameter (D1):

The diameter of the pipe at the inlet section of the Venturimeter.

2. Throat Diameter (D2):

The smallest diameter in the Venturimeter where the fluid velocity reaches its maximum and pressure drops.

3. Overall Length:

The total length of the Venturimeter, typically ranging from 10 to 20 times the throat diameter (10D2 to 20D2).

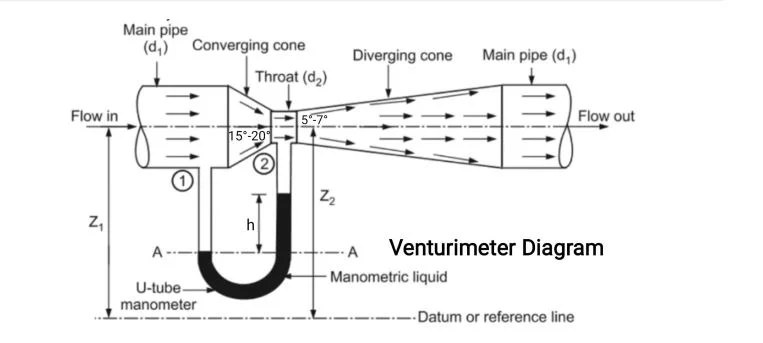

4. Converging Section Angle:

The angle of convergence in the venturimeter’s design, usually around 15 to 20 degrees to facilitate a smooth transition of fluid flow.

5. Diverging Section Angle:

The angle of divergence in the venturimeter’s design, typically around 5 to 7 degrees to allow the fluid to regain its pressure after passing through the throat section.

6. Outlet Diameter (D3):

The diameter of the pipe at the outlet section of the Venturimeter.

7. Pressure Taps:

The presence of pressure taps, typically denoted as P1 (inlet pressure tap) and P2 (throat pressure tap), used to measure the pressure difference for flow rate calculations.

8. Coefficient of Discharge (Cd):

Cd is a ratio that compares the actual flow rate (Qact) through the Venturimeter tube to the theoretical flow rate (Q). Since frictional losses in the system cause the actual flow rate to be lower than the theoretical flow rate, the Cd value is always less than 1.0

Cd=Qact/Q

Working Principle of Venturimeter

The working principle of a venturi meter involves the acceleration and deceleration of fluid flow. As the fluid passes through the venturi meter, it first accelerates in the convergent section and then decelerates in the divergent section. This change in velocity leads to a corresponding change in pressure called Venturi Effect.

The Venturimeter equations are derived from Bernoulli’s principle, according to Bernoulli’s principle, as the fluid’s velocity increases, its pressure decreases. Therefore, at the throat section, where the diameter is at its minimum, the fluid velocity reaches its maximum, resulting in the lowest pressure within the venturimeter. Which relates the pressure, velocity, density, and cross-sectional area of the fluid inside the pipe. By applying Bernoulli’s equation and continuity equation (which ensures mass conservation) between the different sections of the venturi meter, we can derive the following equations.

𝑃1+ρgℎ1+1/2𝜌𝑣12 = 𝑃2+ρgℎ2+1/2𝜌𝑣22

Consider a venturi meter installed in a horizontal pipe to measure the flow of fluid (water)

where:

P1 and P2 = pressures at sections 1 and 2 respectively

ρ = Density of the fluid

g = Acceleration due to gravity

h1 & h2 = Elevations of sections 1 and 2 respectively

v1 & v2 = Velocities of the fluid at sections 1 and 2 respectively

Applying Bernoulli’s equations in sections 1 and 2 of the venturimeter, the rate of flow through the venturi meter can be determined.

P1/ρg + v12/2g + z1 = P2/ρg + v22/2g + z2

Since the pipe is horizontal, the elevation difference between sections 1 and 2 (𝑧1 and 𝑧2) is negligible.

P1/ρg + v12/2g = P2/ρg + v22/2g

(𝑃1-𝑃2)/ρg = (v22 − v12)/2g————— (1)

The difference in pressure heads (𝑃1-𝑃2)/ρg between sections 1 and 2 is equal to h, where ρ is the density of the fluid and g is the acceleration due to gravity. Therefore, the rate of flow through the venturi meter can be calculated as follows:

h = (𝑃1-𝑃2)/ρg

By substituting the values of h (from the previous equations) into equation (1), we can calculate

the rate of flow through the venturi meter

h = (v22 − v12)/2g ——————–(2)

Furthermore, applying the continuity equation at sections 1 and 2, the velocity at section 1 (v1) can be determined:

A1v1 = A2v2

A1 = cross-section area of the inlet pipe at section 1

A2 = cross-section area of the inlet pipe at section 2

By substituting this value of v1 into equations (2) and solving, we can obtain the velocity at

section 2,

v2 = (A1√2𝑔ℎ)/√(𝐴12 − 𝐴22)

Finally, the discharge (Q) through the venturi meter can be calculated:

Q = A2v2

Substituting the value of v2 into the above equation, we get

Q = A2A1√2𝑔ℎ)/√(𝐴12 − 𝐴22)

However, it’s important to note that the theoretical discharge (Q) is obtained under ideal conditions. The actual discharge will be less than the theoretical discharge, and it is given by the formula:

Actual discharge = Q*Cd

𝑄𝑎𝑐𝑡 = 𝐶𝑑A2A1√2𝑔ℎ)/√(𝐴12 − 𝐴22)

Here, Cd represents the coefficient of the venturimeter, which is a value less than 1.

Parts of Venturimeter

The main components of a venturimeter include

1. Inlet Section:

The inlet section is where the fluid enters the venturimeter. It is typically a straight pipe section that connects to the upstream piping system.

2. Converging Section:

The converging section is a tapered portion of the venturimeter that gradually reduces the diameter of the pipe. It helps to increase the fluid velocity and direct the flow towards the throat section.

3. Throat Section:

The throat section is the narrowest part of the venturimeter. It has a fixed diameter and is responsible for creating a constriction in the flow path. The constriction causes a pressure drop in the fluid, which is crucial for flow rate measurement.

4. Diverging Section:

The diverging section follows the throat section and gradually expands the diameter of the pipe. It allows the fluid to decelerate and regain some of the pressure lost at the throat section.

5. Outlet Section:

The outlet section of the venturimeter is where the fluid exits the device. It is typically a straight pipe section that connects to the downstream piping system.

6. Recovery Cone:

Some venturimeters may include a recovery cone at the outlet section. The recovery cone helps the fluid fully recover its pressure and regain a more uniform flow profile as it exits the venturimeter.

7. Pressure Taps:

Venturimeters have pressure taps at specific locations to measure the pressure difference across the throat section. These pressure taps are usually located at the inlet and throat sections and are connected to pressure gauges or transducers for pressure measurement.

8. U-Tube Manometer:

It consists of a U-shaped tube partially filled with a liquid, such as water or mercury. The manometer is connected to pressure tapping points on the venturi meter, allowing the measurement of the pressure differential. These components work together to create a controlled flow path within the venturimeter, allowing for accurate measurement of fluid flow rates based on the pressure difference across the throat section.

YOU CAN ALSO READ Performance characteristics test of a Centrifugal Pump.

Applications of Venturimeters

Venturimeters are commonly used in fluid mechanics and engineering applications for measuring the flow rate of fluids. They utilize the principle of Bernoulli’s equation to determine the flow velocity of a fluid by measuring the pressure difference before and inside a constricted section of the flow path. Here are some applications of venturi meters:

1. Flow Measurement in Pipes:

Venturi meters are frequently used to measure the flow rate of liquids and gases in pipes. They are especially useful for applications where accurate flow measurement is required, such as in industrial processes, water distribution systems, and HVAC systems.

2. Water Supply Systems:

Venturi meters are used in water supply systems to measure the flow of water in pipes. They provide accurate and reliable measurements, making them essential in managing water resources and optimizing water distribution.

3. Fuel Consumption Measurement:

Venturi meters are employed in automotive and aerospace industries to measure the fuel consumption rate in vehicles and aircraft. By accurately measuring the flow rate of fuel, engineers can assess fuel efficiency, optimize engine performance, and monitor consumption.

4. Environmental Monitoring:

Venturi meters find application in environmental monitoring systems, such as air quality monitoring stations. They help measure the flow rate of gases, such as air pollutants, to assess the level of contamination and evaluate the effectiveness of pollution control measures.

5. Process Control:

In various industrial processes, precise flow control is crucial for maintaining efficiency and ensuring product quality. Venturi meters play a role in process control systems by providing real-time flow rate measurements, allowing for adjustments and optimization of the process parameters.

6. Irrigation Systems:

Venturi meters are employed in agricultural irrigation systems to measure the flow rate of water. This information helps farmers manage water usage, plan irrigation schedules, and ensure crops receive the appropriate amount of water for optimal growth.

7. Laboratory and Research Applications:

Venturi meters are also used in laboratories and research facilities for fluid dynamics experiments and studies. They enable researchers to measure and analyze fluid flow characteristics under controlled conditions.

Advantages of Venturimeters

Venturi meters offer several advantages that make them a popular choice for flow rate measurement in various applications. Here are some of the key advantages of venturi meters:

1. Accurate Flow Measurement:

Venturi meters provide accurate and reliable measurements of flow rates. The design of the venturi tube and the principle of Bernoulli’s equation allow for precise calculation of flow velocities based on pressure differentials. This accuracy is particularly important in applications where precise flow control or billing is required.

2. Wide Range of Flow Rates:

Venturi meters can effectively measure a wide range of flow rates, from low to high velocities. They are capable of handling both laminar and turbulent flow conditions, making them versatile for different fluid types and flow regimes.

3. Minimal Pressure Loss:

Venturi meters offer low pressure loss compared to some other flow measurement devices. The gradually tapered shape of the venturi tube minimizes turbulence and pressure drop, ensuring efficient flow through the meter. This advantage is particularly beneficial in applications where energy conservation and system efficiency are critical.

4. Robust and Durable Construction:

Venturi meters are typically made of durable materials such as stainless steel or high-quality plastics. This construction makes them resistant to corrosion, erosion, and wear, ensuring long-term reliability and minimal maintenance requirements.

5. Simple Installation and Maintenance:

Venturi meters are relatively easy to install and require minimal ongoing maintenance. They do not have any moving parts, which reduces the risk of mechanical failures. The absence of moving components also means that venturi meters do not require frequent recalibration or adjustments.

6. Cost-Effective Solution:

Venturi meters are generally cost-effective compared to some alternative flow measurement devices, such as electromagnetic or ultrasonic flowmeters. They offer a good balance between cost, accuracy, and durability, making them a practical choice for many applications.

7. Compatibility with Various Fluids:

Venturi meters can be used to measure the flowrates of various fluids, including liquids and gases. They can handle different fluid viscosities and densities, making them suitable for a wide range of industries and applications.

Limitations and Considerations

While venturi meters offer several advantages, it’s important to consider their limitations andspecific factors when choosing to use them. Here are some limitations and considerationsassociated with venturi meters:

1. Flow Profile Disturbance:

Venturimeters can cause some disturbance to the flow profile, particularly during the contraction and expansion sections of the meter. This can lead to turbulence and inaccuracies in the flow measurement. It’s essential to ensure that the meter is installed correctly and that the upstream and downstream piping configurations meet the recommended guidelines.

2. Pressure Drop:

Although venturimeters have lower pressure losses compared to some other flow measurement devices, they still create a pressure drop in the system. In applications where minimizing pressure loss is critical, alternative flow measurement technologies, such as ultrasonic or thermal flowmeters, may be more suitable

3. Limited Rangeability:

While venturimeters can measure a wide range of flow rates, their accuracy and turndown ratio (the ratio of the maximum to minimum flow rate measurable with acceptable accuracy) are limited. In applications where a broad range of flow rates needs to be accurately measured, alternative flow measurement devices may be preferable.

4. Flow Condition Requirements:

Venturimeters require a fully developed and symmetrical flow profile to provide accurate measurements. They may not perform optimally if the flow is not fully developed, has high turbulence, or exhibits swirling or asymmetrical characteristics. Proper upstream and downstream straight pipe lengths are typically necessary to ensure optimal flow conditions.

5. Fluid Compatibility:

While venturimeters can handle a wide range of fluids, including liquids and gases, certain fluid properties can affect their performance. Factors such as high viscosity, presence of solids or debris, and high temperature can impact the accuracy and longevity of the meter. In such cases, alternative flow measurement devices that are specifically designed for those fluids should be considered.

6.Installation Requirements:

Correct installation is crucial for the accurate performance of venturi meters. They require precise alignment and positioning within the piping system. It is essential to follow manufacturer guidelines and consider factors such as upstream and downstream piping conditions, proper pipe size selection, and proper sealing to minimize installation-related issues.

7. Calibration and Maintenance:

While venturimeters generally require minimal maintenance, periodic calibration and verification of their performance are recommended to ensure accurate measurements over time. Depending on the application and industry requirements, regular calibration may be necessary.

Calibration and Accuracy of Venturimeters

Calibration and accuracy are essential aspects of venturi meters to ensure reliable flow measurements. Here’s some calibration process and the accuracy of venturi meters discussed.

Calibration of Venturi Meters:

1. Standard Calibration:

Venturimeters are typically calibrated using reference standards, such as volumetric tanks or master flow meters, to establish their flow measurement accuracy. The calibration process involves comparing the readings obtained from the venturi meter with the known flow rates provided by the reference standard.

2. Laboratory Calibration:

Venturimeters can be calibrated in specialized laboratories that have the necessary equipment and expertise to conduct precise flow measurements. The laboratory calibration ensures accurate and traceable calibration results, which are essential in applications where precise flow rate measurements are critical.

3. Field Calibration:

In some cases, venturimeters can be calibrated in the field using portable calibration equipment. This allows for periodic checks and adjustments of the meter’s performance without the need for removal or replacement.

Accuracy of Venturi Meters:

1. Published Accuracy Specifications:

Manufacturers provide accuracy specifications for their venturi meters, indicating the acceptable level of error in flow measurements. The accuracy is typically expressed as a percentage of the measured flow rate or a specified number of flow rate increments.

2. Turndown Ratio:

The accuracy of a venturimeter can vary across different flow rates. Manufacturers often specify the turndown ratio, which is the ratio between the maximum and minimum flow rates at which the meter can provide accurate measurements. It is important to consider the intended operating range and ensure the venturi meter’s accuracy is appropriate for the desired flow rates.

3. Installation Factors:

Proper installation and adherence to recommended installation guidelines play a crucial role in achieving accurate flow measurements with venturi meters. Factors such as upstream and downstream pipe lengths, flow straighteners, and pipe alignment can affect the meter’s accuracy. Following manufacturer instructions and industry best practices during installation is important for optimal performance.

4. Fluid Properties:

The accuracy of venturimeters can be influenced by the properties of the fluid being measured, such as viscosity, density, and temperature. It is important to ensure that the meter is suitable for the specific fluid being measured and that any fluid property variations are within the meter’s specified range.

5. Maintenance and Recalibration:

Regular maintenance and periodic recalibration are essential to maintain the accuracy of venturimeters over time. Factors such as wear and tear, fouling, or changes in the flow profile can impact the meter’s performance. It is recommended to follow the manufacturer’s maintenance guidelines and schedule recalibration as per industry standards or specific application requirements.

Difference Between Venturimeter and Orificemeter

The venturimeter and orifice meter are both commonly used flow measurement devices, but they have distinct differences in terms of their design, principle of operation, and application. Here are the key differences between a venturimeter and an orifice meter

| Sl No. | SUBJECT | VENTURIMETER | ORIFICEMETER |

| 1 | Design and Structure: | A venturimeter has a converging section followed by a throat section and a diverging section. It typically features a gradual taper in the converging and diverging sections to optimize fluid flow. | An orifice meter consists of a flat plate or a circular disc with a precisely drilled hole, known as the orifice plate. The orifice plate is placed in a straight pipe section, creating a flow restriction |

| 2 | Flow Profile: | The venturimeter creates a gradual transition from a larger pipe diameter to a smaller throat diameter and then back to a larger diameter. This results in a more uniform flow profile downstream of the venturimeter. | The orifice meter causes a sudden and sharp disruption in the flow due to the presence of the orifice plate. This leads to a more turbulent flow downstream of the orifice plate. |

| 3. | Pressure Recovery | The venturimeter is designed to promote pressure recovery. It includes a diverging section and, in some cases, a recovery cone at the outlet, which helps the fluid regain its pressure to a significant extent | The orifice meter has relatively lower pressure recovery compared to the venturimeter. The abrupt change in flow area at the orifice plate leads to higher pressure losses downstream. |

| 4. | Accuracy and Range: | Venturimeters offer higher accuracy in flow measurement compared to orifice meters. They are suitable for a wide range of flow rates, from low to high velocities. | Orifice meters provide acceptable accuracy for a range of flow rates |

| 5. | Cost and Installation: | Venturimeters are generally more expensive to manufacture and install compared to orifice meters due to their complex design and the need for precise tapering. | Orifice meters are relatively more cost-effective and easier to install, as they involve a simple plate installation in the pipe |

| 6. | Application Focus: | Venturimeters are commonly used in applications that require accurate flow measurement, such as research, laboratory testing, and industrial processes where higher accuracy is desired. | Orifice meters are widely used in industrial applications for flow measurement, particularly in large pipe systems and process industries where high accuracy is not critical |

Conclusion

In conclusion, venturimeters are widely used for flow rate measurement in various applications due to their advantages such as accuracy, wide rangeability, low pressure loss, durability, ease of installation and maintenance, cost-effectiveness, and compatibility with different fluids. They utilize the principle of Bernoulli’s equation to measure flow velocity based on pressure differentials.

However, it is important to consider the limitations and factors that can impact the performance of venturimeters. These include flow profile disturbance, pressure drop, limited rangeability, flow condition requirements, fluid compatibility, installation requirements, and the need for calibration and maintenance.

Calibration and accuracy play a vital role in ensuring reliable flow measurements with venturi meters. Calibration can be performed using standard calibration methods in laboratories or in the field using portable calibration equipment. Manufacturers provide accuracy specifications and turndown ratios to indicate the meter’s performance across different flow rates. Factors such as installation, fluid properties, and regular maintenance and recalibration also influence the accuracy of venturimeters.

By considering the specific application requirements, flow characteristics, and accuracy needs, venturimeters can be selected and utilized effectively. It is recommended to consult with experts, follow manufacturer guidelines, and adhere to industry best practices to maximize the accuracy and performance of venturimeters in flow measurement applications.

FAQ Related VENTURIMETER

1. What is calibration of venturimeter?

Calibration of a venturi meter involves comparing its performance and measurements against known reference standards or devices. The purpose is to determine the accuracy and reliability of the venturimeter in measuring fluid flow rates. Calibration ensures that the venturimeter provides accurate readings and allows for adjustments or corrections if necessary

2. What is coefficient of discharge in venturimeter?

The coefficient of discharge (Cd) in a venturi meter is a dimensionless parameter that represents the efficiency or effectiveness of the venturi meter in measuring flow rates. It is the ratio of the actual flow rate through the venturi meter to the theoretical or ideal flow rate. The Cd value considers various factors such as frictional losses, imperfections in the venturi meter design, and flow conditions. It is determined through calibration and is used to adjust the theoretical flow rate to obtain the actual flow rate