Contents

- Introduction

- Bearings Classification

- What is a Sliding Contact Bearing?

- Types of Sliding Contact Bearings

A. Thin Film Lubrication

B. Thick Film Lubrication

-Hydrostatic Bearing

-Hydrodynamic Bearing (Journal Bearing)

Introduction

Bearings are an essential component to every rotational component in a mechanical device. In order for a shaft or spindle to rotate, it must rest on a stationary support which allows it to rotate freely. Such a support is known as the bearing. There is a lot of friction associated with a friction as it constantly rubs against the surface of the shaft; therefore bearings must be so designed that it can resist friction. Else, it will result in a lot of heat and noise generation, consequently affecting the proper functioning of the component adversely.

Bearings Classification

Bearings are broadly classified under two categories:

1. Sliding Contact Bearings, and

2. Rolling Contact Bearings.

In this article, we shall look into various types of Sliding Contact Bearings and their Applications.

What is a Sliding Contact Bearing?

Sliding Contact Bearings are type of bearings in which the space between the bearing housing and the shaft is filled with a lubricating fluid. The shaft stays afloat on this lubricant and slides over it. The crucial parameters that govern the operation of this bearing are- the speed of rotation of the shaft, pressure of the lubricant, film thickness of the lubricant and its viscosity.

Types of Sliding Contact Bearings

A. Thin Film Lubrication

Thin film lubrication is one in which, the layer of lubricant between the bush and the shaft is thin. Whether the lubricant film is thick or thin, is decided by a parameter known as the Bearing Characteristic Number (BCN). It takes into account the rotational sped of the shaft, the thrust on the bearing and the viscosity of the lubricant. When the Bearing Characteristic Number (BCN) is below a certain critical value, it is called thin film lubrication.

In this case, there are chances of solid-solid rubbing between the aforementioned components. Therefore, the general range of coefficient of friction in this case is quite higher. This type of lubrication is generally not preferred in most of the bearing applications and these are used only in very specific cases.

B. Thick Film Lubrication

In thick film lubrication, as the name suggests, the layer of the lubricant is comparatively thicker and it ensures that solid-solid friction between the shaft and the bush is prevented at all costs. This is the most preferred type of bearing for all general applications.

When the Bearing Characteristic Number (BCN) is above the critical value, then it is termed as thick film lubrication.

Thick film lubrication is further classified as-

1. Hydrostatic Lubrication

2. Hydrodynamic Lubrication (Journal Bearing)

B-1. Hydrostatic Bearing

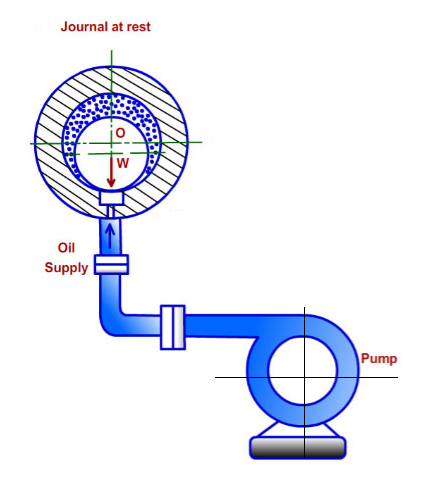

Hydrostatic Lubrication is generally used for heavy duty applications and has high load carrying capacity. The weight of the shaft and the allied components are supported by a pressurized lubricant, which is externally pressurized using a pump.

B-2. Hydrodynamic Bearing (Journal Bearing)

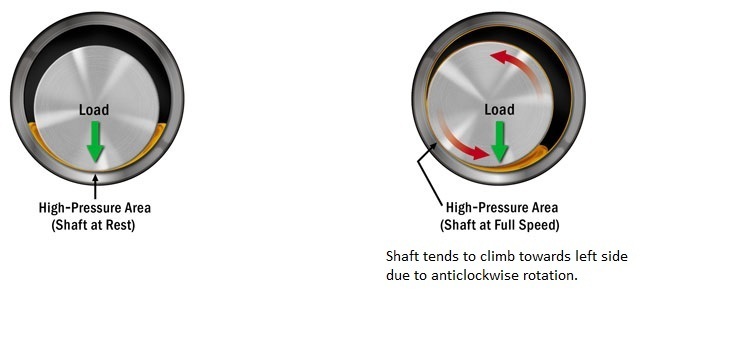

It is the most general and commonly used case of Thick Film Lubrication. The shaft rests in a thick film of lubrication and in static condition, the shaft sinks into the lubricant and touches the bush. In other words, the axis of the shaft shifts slightly downwards from the center line of the bearing cavity.

When the shaft starts to rotate, it tends to climb onto the surface of the journal and pressure is developed due to compressive forces. This pressure pushes the shafts onto the other side and finally under dynamic equilibrium, the center lines shaft and the bush cavity finally coincides and ideal operative condition is established.

- This type of bearing is most commonly seen in day to day applications.

- Starting friction is high and friction reduces with increase in speed.

- Load carrying capacity is comparatively low.

- Generally it carries radial loads, but modified versions such as Foot Step Bearing or Collar Bearing can carry axial loads as well.