Robot makers are revolutionizing manufacturing by providing powerful, automated systems that can increase productivity and reduce costs. The use of industrial robots has been growing rapidly in recent years, and many companies are collaborating with robot makers to keep them stay competitive in business. In this article, we’ll take a look at how robot makers are revolutionizing manufacturing, the different types of industrial robot manufacturers, and what to consider when selecting an industrial robot maker. We’ll also discuss the challenges and opportunities for robot makers, automation and robotics in manufacturing, and the advantages of using industrial robot manufacturers.

Table of Contents

Introduction to Robot Makers

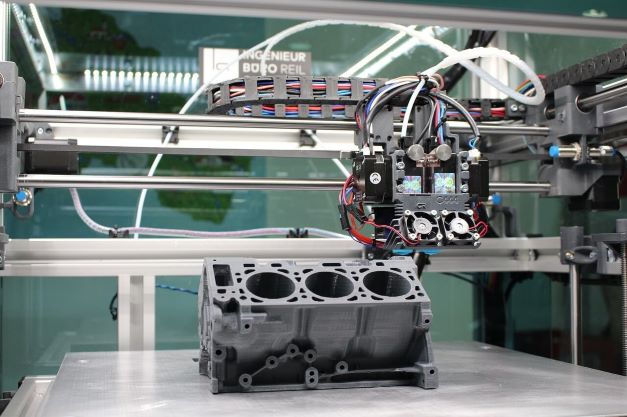

Robot makers are companies that specialize in creating industrial robots. These robots are designed to perform specific tasks in manufacturing and industrial processes. They are usually programmed to carry out repetitive and precise tasks with precision and speed. Some robot makers specialize in producing robots for specific industries, while others offer a range of robots for different applications.

Robot makers use advanced technologies to make their robots more efficient and reliable. They also use computer-aided design (CAD) to create designs that can be used to program the robots. The robots are then built with components sourced from reliable suppliers to ensure quality and reliability.

How Robot Makers are Revolutionizing Manufacturing

Robot makers are revolutionizing manufacturing by providing efficient, automated systems that can automate repetitive tasks and reduce costs. Robots can be used to handle heavy loads, operate in hazardous environments, and perform complex tasks that may be too difficult or dangerous for humans. This reduces the need for manual labor, which can be expensive and unreliable.

Robots can also be programmed to work in collaboration with other machines, which increases the efficiency of production lines. This can help manufacturers keep up with changing demand and reduce wastage. Additionally, robots can be used to monitor production processes and alert operators to any problems, which helps to reduce downtime and improve quality control.

Robot makers are also helping to reduce the environmental impact of manufacturing. They are developing robots that can operate with fewer resources and reduce energy consumption. This can help manufacturers reduce their carbon footprint and save money in the long term.

Benefits of Using Robot Makers

The use of robot makers can bring a number of benefits to manufacturers. These include:

1. Increased efficiency:

Robots can operate with greater precision and speed than humans, which can help to reduce waste and increase productivity.

2. Reduced costs:

By automating processes and eliminating the need for manual labor, robot makers can help to reduce costs and improve profitability.

3. Improved quality control:

Robots can be programmed to monitor production processes and alert operators to any problems, which helps to reduce downtime and improve quality control.

4. Increased safety:

Robots can operate in hazardous environments that may be too dangerous for humans, which can improve safety and reduce the risk of accidents.

5. Reduced environmental impact:

Robots can operate with fewer resources and reduce energy consumption, which can help to reduce a manufacturer’s carbon footprint.

The Different Types of Industrial Robot Manufacturers

Robot makers specialize in creating different types of robots for different applications. Some of the most common types of robots include:

1. Assembly robots:

These robots are used to assemble components and assemble products. They can be programmed to carry out tasks with precision and speed.

2. Welding robots:

These robots are used to weld components and products together. They can be programmed to carry out the welding process with precision and accuracy.

3. Pick and place robots:

These robots are used to pick up, move, and place objects. They can be programmed to move objects with precision and speed.

4. Inspection robots:

These robots are used to inspect products and components. They can be programmed to detect defects and alert operators to any problems.

5. Palletizing robots:

These robots are used to load and unload pallets. They can be programmed to load and unload pallets with precision and speed.

What to Consider When Selecting an Industrial Robot Maker

When selecting an industrial robot maker, there are a few things to consider. Most important things are

1. Reputation:

It’s important to check the reputation of the robot maker before making a decision. Check previous customer reviews and their product what are already in use.

2. Expertise:

Make sure the robot maker you choose has expertise in the type of robot you need. Check to see if they have experience designing and building robots for the type of application you require.

3. Cost:

The cost of the robot maker should also be taken into account. Make sure you get a good deal by comparing prices and looking for special offers.

4. Support:

It’s important to choose a robot maker that offers good after-sales support. This includes training and technical support in case of problems.

Challenges and Opportunities for Robot Makers

Robot makers face a number of challenges, as well as opportunities. These include:

1. Increasing competition:

The market for robot makers is becoming increasingly competitive, with new companies entering the market all the time. This means that robot makers need to constantly innovate and stay ahead of the competition.

2. Emergence of new technologies:

The emergence of new technologies such as artificial intelligence and machine learning is creating opportunities for robot makers to create more powerful and intelligent robots.

3. High costs:

Developing and building robots can be expensive, and robot makers need to find ways to reduce costs and increase efficiency.

4. Lack of skilled workers:

Finding skilled workers to design and build robots can be difficult, and robot makers need to find ways to train and retain their staff.

Automation and Robotics in Manufacturing

Automation and robotics are increasingly being used in manufacturing processes. Automation is the use of machines to automate processes, while robotics involves the use of robots to carry out specific tasks. Automation and robotics can help manufacturers reduce costs, increase efficiency, and improve the quality of products.

Robotics is used in a variety of manufacturing processes, such as assembly, welding, inspection, and palletizing. Automation can also be used to monitor production processes and alert operators to any problems. Automation and robotics can also be used to reduce energy consumption and waste.

Popular Industrial Robot Manufacturers

There are a number of popular industrial robot manufacturers. These include:

1. ABB:

ABB is a Swiss-based industrial robot manufacturer that specializes in creating robots for a variety of applications.

2. Kuka:

Kuka is a German-based industrial robot manufacturer that specializes in creating robots for the automotive industry.

3. Fanuc:

Fanuc is a Japanese-based industrial robot manufacturer that specializes in creating robots for the manufacturing industry.

4. Yaskawa:

Yaskawa is a Japanese-based industrial robot manufacturer that specializes in creating robots for the medical and healthcare industries.

5. Mitsubishi:

Mitsubishi is a Japanese-based industrial robot manufacturer that specializes in creating robots for the food and beverage industry.

Robot makers are revolutionizing manufacturing and creating a more efficient and sustainable industry. By selecting the right robot maker and taking advantage of their services, manufacturers can reap the benefits of using robots in their operations. With the right robot maker, manufacturers can increase efficiency, reduce costs, and improve quality control.

If you are planning to buy a new telescope within budget, here are 5 Best Telescope For Seeing Planets And Galaxies Of 2023.

Robot Maker Services

Robot makers offer a range of services to help manufacturers get the most out of their robots. These services include:

1. Design and engineering:

Robot makers can design and engineer robots for specific applications. They can also provide custom solutions to meet the needs of the customer.

2. Training and support:

Robot makers can provide training and support to help manufacturers get the most out of their robots. This includes troubleshooting and maintenance support.

3. Installation and maintenance:

Robot makers can provide installation and maintenance services to ensure that robots are running efficiently and reliably.

4. Upgrades and modifications:

Robot makers can provide upgrades and modifications to help keep robots up to date with the latest technology.

Conclusion

Robot makers are revolutionizing manufacturing by providing efficient, automated systems that can automate repetitive tasks and reduce costs. They are using advanced technologies to make their robots more efficient and reliable, and they are developing robots that can operate with fewer resources and reduce energy consumption. Robot makers offer a range of services to help manufacturers get the most out of their robots, and they face a number of challenges and opportunities.

Robot makers are helping to revolutionize manufacturing and create a more efficient and sustainable industry. By selecting the right robot maker and taking advantage of their services, manufacturers can reap the benefits of using robots in their operations.

Revolutionizing Manufacturing: How Robot Makers are Transforming the Industry robot-makers-are-transforming-manufacturing-industry