Particulate Matter

The air that surrounds us consists of many different components including various gases and other constituents such as water vapour and suspended particulate matters (SPMs). Among these particulates, those of diameter less than 2 μm, which originate from sources such as incinerators, boilers, and automobiles are of serious concern because they may reach deeply into human lungs during breathing and cause respiratory diseases.

Aerosols, combustion particles, crystal materials, fugitive dusts are some examples of such particulate matters. Production of these particulates is an inevitable part of operation of most of the power plants and industries. The only option is to figure out ways to filter them in an efficient way. In the ensuing article, we shall look into various methods by which we can attain this goal.

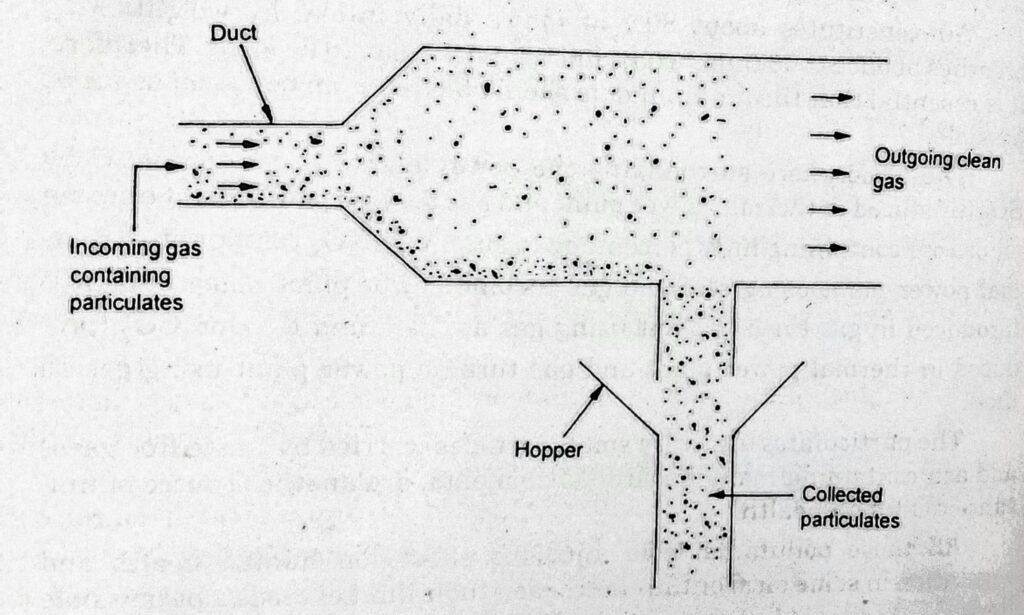

I. CHANGING THE CROSS SECTIONAL AREA OF FLOW

This is a very simple method to filter out particulates from flue gas. In this method, the cross sectional area through which the gases are passed is increased and consequently, the velocity of the flow is reduced as per the continuity equation. As a result of slowing down, the particles tend to settle down and are made to drop into a hopper and filtered out.

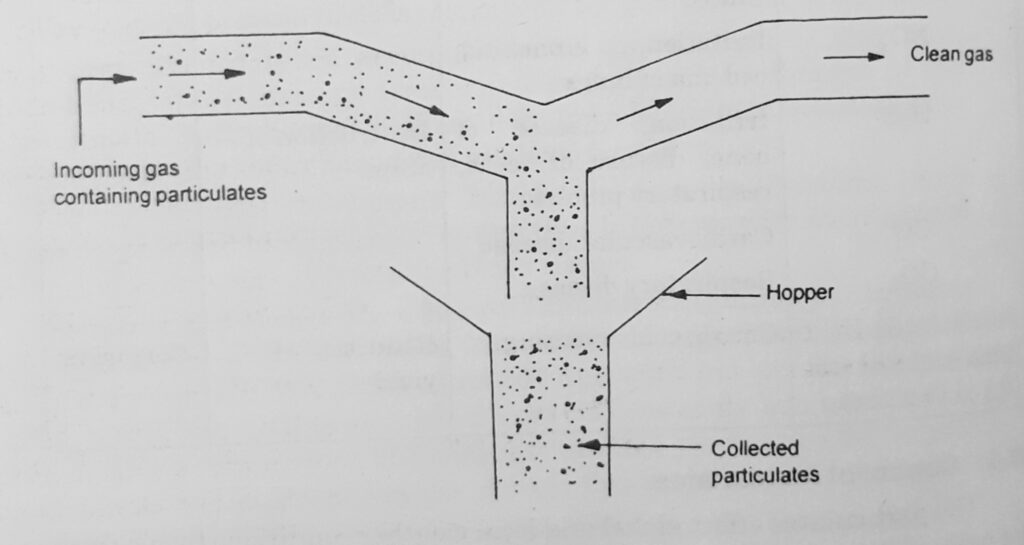

II. FLOW DIRECTION CHANGER

It is another simple method of particulate controlling in which the direction of flow of gases is changed abruptly. Due to this, turbulence is caused in the flow and the heavier particles fail to keep up pace with the lighter air airstream and consequently they get settled down.

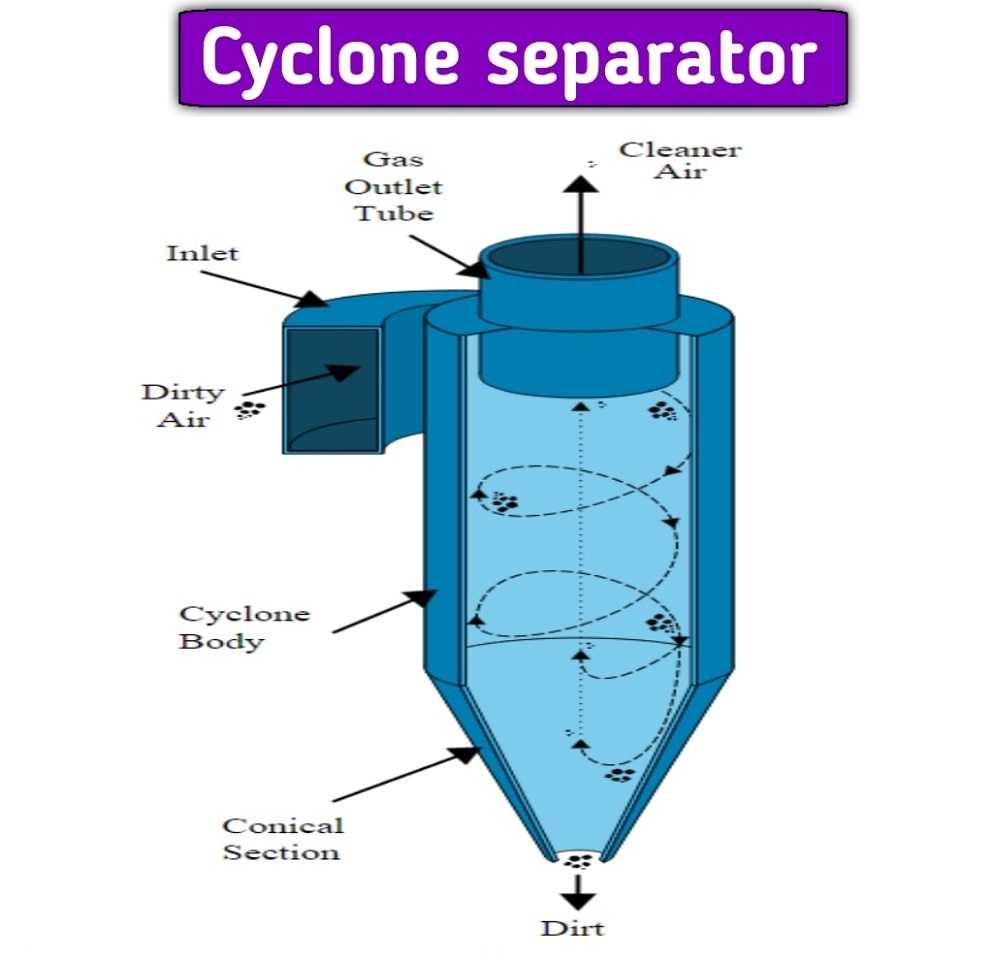

III. CYCLONE SEPARATOR

Cyclone separator is a mechanical type of separator where a high velocity gas stream carrying dust particles enters tangentially to the conical shell. This produces whirling of the gas and throws heavy dust particles to the sides of the conical shell. These particles are collected at the bottom of the separator. The gas from the conical shell is passed through the secondary chamber for final separation of dust particles.

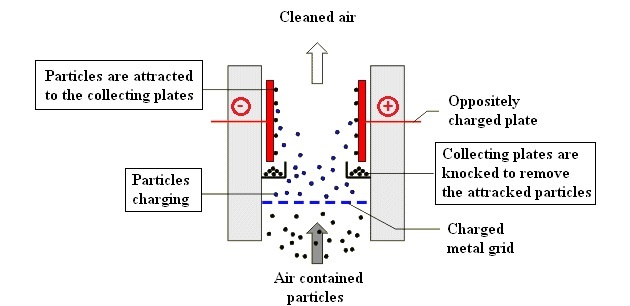

IV. ELECTROSTATIC PRECIPITATOR

Two plates are charged oppositely at high voltage using Direct Current (D.C.). When the gas carrying the particulates is passed between these plates, it becomes ionised and most of the positively charged particulates are deposited on the discharge electrode from which they accumulate at the bottom due to vibrating motion caused to the discharge electrode. These particulates are removed to a pond where they are mixed with water.

The clean gas then leaves the electrostatic precipitator through an outlet at the top of the precipitator.