CONTENTS

- Introduction

- How Gas Turbine works?

- Thermodynamic Cycle used

- Boosting the performance of a gas turbine

-Regeneration

-Reheating

-Intercooling

Introduction

In this article, we shall discuss about Gas Turbines, their uses and how their working is modified as per needs. We’ll also look at the Brayton Cycle or Joule Cycle which is used for running a Gas Turbine.

Simply put, Gas Turbine is a power generating device, which uses fuels like natural gas and derive shaft power from it. This rotational power of the shaft can then be used to produce electricity or can be directly used to do some mechanical work. It is very useful in remote places where there is no electricity connection.

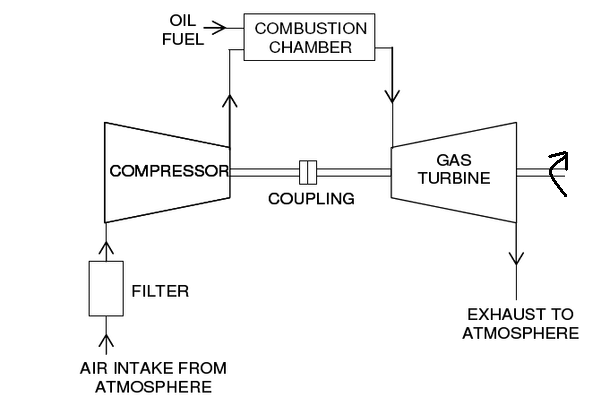

How Gas Turbine Works?

Air from the atmosphere is sucked into a compressor and and pressurized and delivered to the combustion chamber. It is the place where the fuel is ignited and the compressed air helps in the combustion of the fuel. The compressed air absorbs a lot of heat energy from this combustion and its temperature rises. This high pressure high temperature air is then used to drive a turbine, from which the rotational power is obtained.

Note that the flue gases evolved due to combustion of the fuel gets mixed with the air and it is also used in driving the turbine.

Remember that we used a compressor at the very beginning? How does it run? It should also consume some energy, right? So, a part of the power generated by the turbine is actually used up in driving the compressor.

Thermodynamic Cycle Used

We know that every work producing device using heat energy must follow some thermodynamic cycle for producing the work. Let’s have a look at it for the case of Gas Turbine.

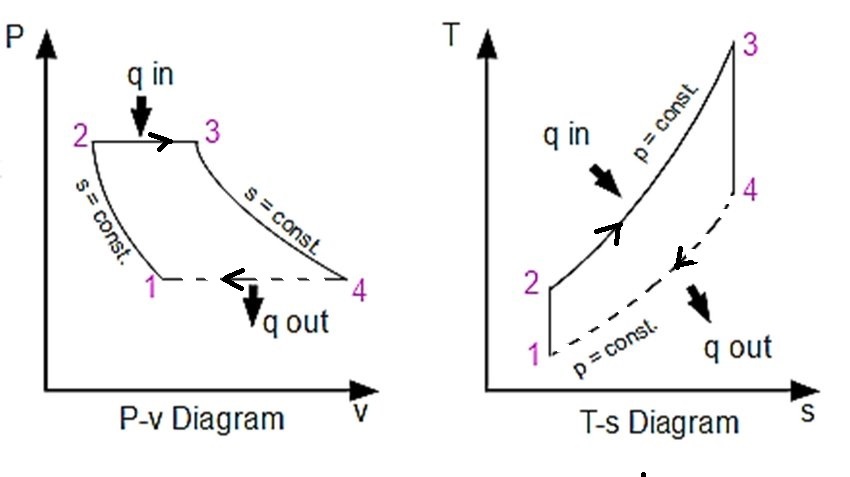

In the case of Gas Turbine, Brayton Cycle or Joule Cycle is used to power the device. The working medium (air) undergoes this cycle.

It is a simple thermodynamic cycle comprising of two constant pressure processes and two adiabatic processes. The working fluid is air.

Let’s have a look at the various processes:

1-2: Isentropic compression; takes place in the Compressor, Air is drawn into the compressor from the atmosphere at the point 1. The air gets compressed and consequently is temperature rises, volume decreases and pressure increases.

2-3: Constant pressure heat addition; this process takes place within the combustion chamber, where the heat is added to the working medium (air).

3-4: Isentropic expansion process; this process takes place in the turbine. The pressure is dropped and temperature gets reduced. At point 4, the air is released to the atmosphere.

4-1: This is a pseudo process. It is a part of the original Brayton/Joule cycle but this process is not executed as such, in case of an open cycle gas turbine. It simply depicts the transition of state from the discharged air of the turbine to the air intake at the compressor.

Boosting the performance of a gas turbine

In general, the efficiency of a gas turbine is low and net work output is also low because a large part of the work produced is used up in running the compressor, which is a part of the power producing process itself. So, the following methods are often adopted to improve the performance of a gas turbine.

A. REGENERATION

The air at the turbine exit is still hot and has a lot of energy left which could not be extracted fully by the turbine. Regeneration is a process wherein the exhaust gases from the turbine are used to heat air at the turbine exit.

Regeneration is highly helpful to increase the efficiency of the whole system although the net work output remains unchanged.

B. REHEATING

In this process, the gases at the exit from the combustion chamber is expanded in a turbine but only upto a certain limit. After that, the gases are again heated and then again they are passed trough another turbine.

This process harms (reduces) the overall efficiency but is helpful to increase the net power output, if it is required.

C. Intercooling

In this process, a device called intercooler is employed to reduce the work spent in compressing the air. The intake air from the atmosphere is partially compressed and then it is cooled in the intercooler and then it is again compressed by the help of another compressor. Due to cooling, the volume of air gets reduced and hence less bulky and less work is required to compress it.

This process is also used to increase the net work output but it reduces the overall efficiency.