The purpose of this article is to provide a comprehensive overview of drum brakes, covering their components, functioning, advantages, and limitations. By exploring the various aspects of drum brakes, readers will gain a clear understanding of how these brakes work, their key components, and their role in the overall automotive system. Additionally, the article aims to highlight the advantages of drum brakes, such as cost-effectiveness, simplicity, and durability, while also addressing their limitations, including heat dissipation, brake fading, and performance in wet conditions. By providing a thorough examination of drum brakes, readers will be equipped with the knowledge to better understand and appreciate the significance of this braking system in different vehicles.

Table of Contents

Introduction

Drum brakes are a type of braking system commonly used in vehicles, including cars, motorcycles, and heavy-duty vehicles. They are named after their drum-shaped components, which rotate with the wheel and provide the braking surface.

The importance of Drum brakes in the automotive system lies in their ability to convert kinetic energy into heat energy, effectively slowing down or stopping the vehicle. They play a crucial role in ensuring the safety and control of the vehicle by providing reliable braking performance.

Drum brakes are particularly significant in the following vehicles:

- Cars: Drum brakes are commonly found in the rear wheels of many cars. They offer reliable braking performance, especially in lighter vehicles where the braking demands may not be as extreme as in heavy-duty applications.

- Motorcycles: Drum brakes have been traditionally used in motorcycles, particularly in older models. While disc brakes are now more common in modern motorcycles, drum brakes are still used in certain applications due to their simplicity, cost-effectiveness, and adequate braking performance.

- Heavy-Duty Vehicles: Drum brakes are widely utilized in heavy-duty vehicles, such as trucks, buses, and commercial vehicles. These vehicles often require robust braking systems capable of handling higher loads and braking demands. Drum brakes provide the necessary braking force and durability required in these applications.

The significance of drum brakes in these vehicles lies in their ability to provide reliable braking performance, affordability, and durability. While disc brakes offer certain advantages in terms of heat dissipation and braking efficiency, drum brakes continue to be employed in various vehicles due to their suitability for specific applications and their ability to meet the required braking standards.

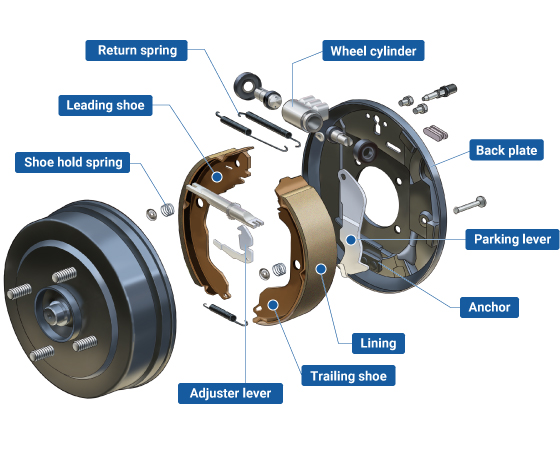

Components of Drum Brakes

The components of drum brakes include:

- Drum: The drum serves as the primary component of the brake assembly in drum brakes. It is a circular, hollow structure that attaches to the wheel hub. When the brake shoes press against the inner surface of the drum, friction is generated, allowing the vehicle to slow down or stop. The drum provides the necessary surface area and contact with the brake shoes to facilitate braking action.

- Shoes: Brake shoes are curved metal components lined with friction material in drum brakes. Their function is to create friction against the inner surface of the drum when the brakes are applied. As the brake shoes are forced against the drum, the friction material generates resistance, converting the kinetic energy of the rotating drum into heat energy, ultimately slowing down or stopping the vehicle.

- Wheel Cylinder: The wheel cylinder is a hydraulic device located inside the brake drum. It consists of pistons and seals and is responsible for converting hydraulic pressure from the brake system into mechanical force. When hydraulic pressure is applied, the wheel cylinder extends its pistons, pushing the brake shoes against the drum.

- Brake Springs: Brake springs are essential for the proper functioning of drum brakes. They are responsible for returning the brake shoes to their original position after the brakes are released. The springs help retract the brake shoes away from the drum, preventing unnecessary friction and dragging.

- Adjuster Mechanism: The adjuster mechanism ensures that the proper clearance is maintained between the brake shoes and the drum. It consists of various components such as an adjuster lever, star wheel, and self-adjuster mechanism. The adjuster mechanism automatically adjusts the position of the brake shoes as they wear down, compensating for the material loss and maintaining optimal braking performance.

- Backing Plate: The backing plate provides a rigid support structure for the other components of the drum brake system. It holds the wheel cylinder, brake shoes, and other hardware in place, ensuring their proper alignment and functioning.

- Return Spring: The return spring assists in retracting the brake shoes after braking. It helps restore the brake shoes to their original position when the brake pedal is released, allowing the drum to rotate freely without any frictional contact.

- Lining: The lining refers to the friction material attached to the brake shoes. It is the component that comes into contact with the drum to create the necessary friction for braking.

- Parking Lever: The parking lever, also known as the parking brake lever or parking brake actuator, is a mechanism that engages the parking brake in drum brake systems.

- Anchor: The anchor refers to a fixed or stationary component that holds the brake shoes in place. It is typically a metal bracket or plate secured to the backing plate of the brake assembly.

These components work together to convert hydraulic or mechanical force into frictional force, enabling the vehicle to slow down or come to a complete stop. The drum, brake shoes, wheel cylinder, springs, adjuster mechanism, backing plate, and return spring collectively form a functional drum brake assembly.

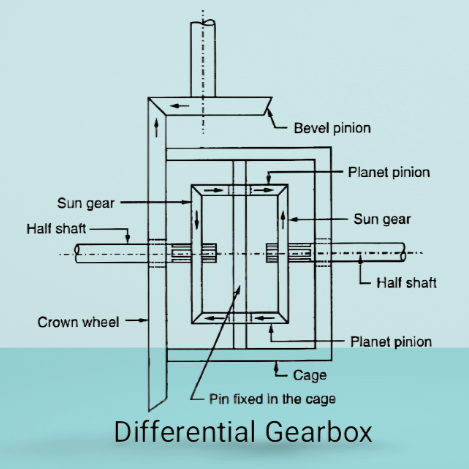

YOU CAN ALSO READ TOP 10 MOST COMMON GEARBOX TRANSMISSION PROBLEMS & ITS TROUBLESHOOTING.

Working of Drum Brakes

Drum brakes can operate through hydraulic, pneumatic, or mechanical systems. Here’s a brief explanation of the working principles of drum brakes:

A. Application of Braking Force:

When the brake pedal is pressed, the braking force is applied to the drum brakes. This force is transmitted to the brake shoes through various mechanisms, such as hydraulic pressure, pneumatic pressure, or mechanical linkage. The brake shoes are then forced against the inner surface of the drum, creating friction and generating braking force.

B. Hydraulic System:

In hydraulic drum brakes, the hydraulic system plays a crucial role. When the brake pedal is pressed, it activates the master cylinder, which creates hydraulic pressure. This pressure is transmitted through brake lines to the wheel cylinders located inside the brake drums. The wheel cylinders extend, pushing the brake shoes against the drum and generating the braking force.

C. Friction and Heat Generation:

During braking, the friction material on the brake shoes creates friction against the rotating drum. This friction converts the kinetic energy of the moving vehicle into heat energy. The generated heat is dissipated through the drum and other components, allowing the vehicle to slow down or stop.

D. Brake Fade:

Brake fade refers to the gradual loss of braking effectiveness due to excessive heat buildup. As drum brakes operate, the continuous friction and heat generation can cause the brake components to overheat. This can lead to reduced friction and a decrease in braking performance. Brake fade can be mitigated through proper maintenance, cooling systems, and using heat-resistant materials.

Working Principles based on different types of drum brakes:

- Leading/Trailing Shoe Type Drum Brake: In a leading/trailing shoe type drum brake, there are two brake shoes: a leading shoe and a trailing shoe. The leading shoe is positioned towards the front of the vehicle’s rotation, while the trailing shoe is placed towards the rear. When the brake pedal is pressed, hydraulic or mechanical force is applied to the wheel cylinder, which pushes the brake shoes outward. The leading shoe makes initial contact with the drum and generates the primary braking force. As the drum rotates, the trailing shoe also comes into contact with the drum, providing additional braking force. This arrangement allows for efficient braking and good stopping power.

- Twin Leading Shoe Drum Brake: In a twin leading shoe drum brake, both brake shoes are leading shoes. This design offers enhanced braking performance compared to the leading/trailing shoe type. When the brake pedal is pressed, hydraulic or mechanical force is applied to the wheel cylinder, pushing both brake shoes outward simultaneously. Both leading shoes make contact with the drum and generate braking force from both sides, resulting in improved braking efficiency. This design is commonly used in high-performance and heavy-duty applications where greater stopping power is required.

- Duo-Servo Drum Brake: In a duo-servo drum brake, the brake shoes are designed with a self-energizing mechanism. When the brake pedal is pressed, hydraulic or mechanical force is applied to the wheel cylinder, causing the brake shoes to move outward and make contact with the drum. As the drum rotates, the rotation of the drum itself helps to push the brake shoes further against the drum, increasing the braking force. This self-energizing effect improves the overall braking performance of the duo-servo drum brake system. Duo-servo drum brakes are commonly used in various vehicles, including passenger cars and commercial vehicles.

These working principles and types of drum brakes ensure reliable braking performance, allowing vehicles to safely slow down or come to a stop.

Advantages and Limitations of Drum Brakes

Advantages of Drum Brakes

- Cost-effectiveness: Drum brakes are generally more affordable compared to other brake systems, such as disc brakes. The simpler design and manufacturing process of drum brakes contribute to their lower cost, making them an economical choice for many vehicles.

- Simplicity: Drum brakes have a straightforward design, consisting of fewer components compared to disc brakes. This simplicity makes them easier to manufacture, install, and maintain. With fewer parts to manage, drum brakes can be more straightforward to service and repair, reducing maintenance complexity and associated costs.

- Durability: Drum brakes are known for their durability and ability to withstand challenging operating conditions. The enclosed design of drum brakes provides protection against external elements such as dirt, dust, and moisture, enhancing their durability. This makes drum brakes suitable for a wide range of vehicles, including those used in off-road, heavy-duty, and high-temperature environments.

- Self-energizing: Some drum brake designs, such as duo-servo brakes, utilize a self-energizing mechanism that enhances their braking efficiency, especially under heavy braking conditions.

- Less susceptible to contamination: Drum brakes are less susceptible to contamination from dirt, debris, and water compared to disc brakes, as the brake components are enclosed within the drum.

- Protection against Contaminants: The enclosed nature of drum brakes offers better protection against contaminants like dust, dirt, and moisture. This can contribute to longer brake component life and reduced maintenance requirements.

- Backward Compatibility: Drum brakes can be easily integrated into older vehicles or those designed with drum brake systems. This backward compatibility allows for seamless replacement or upgrade of brake components without requiring extensive modifications to the vehicle’s braking system.

Limitations of Drum Brakes

- Heat Dissipation: Drum brakes have limited heat dissipation capabilities compared to disc brakes. The enclosed nature of drum brakes restricts the airflow and makes it harder for heat to dissipate, leading to the potential for increased brake temperatures.

- Brake Fading: Drum brakes are prone to experiencing brake fade under heavy and prolonged braking conditions. Brake fade occurs when the friction material of the brake shoes becomes overheated, leading to a decrease in braking effectiveness.

- Performance in Wet Conditions: Drum brakes can experience reduced braking efficiency when exposed to water, as water can affect the friction between the brake shoes and drum, resulting in longer stopping distances.

- Maintenance: Drum brakes require regular adjustments and inspections to ensure optimal performance. They can be more challenging to service and adjust compared to disc brakes.

Weight and Bulkiness: Drum brakes tend to be heavier and bulkier than disc brakes, which can impact the overall weight and design of the vehicle.

It’s important to note that the advantages and limitations of drum brakes can vary depending on the specific design, application, and technological advancements in the brake system. Manufacturers continue to improve drum brake designs to mitigate some of the limitations and enhance their performance.

Comparison Drum Brakes vs Disc Brakes

Drum brakes and disc brakes are the two main types of braking systems used in vehicles. Here is a brief comparison between the two:

Aspect | Drum Brakes | Disc Brakes |

| Design and Functioning: | Drum brakes consist of brake shoes that press against the inside surface of a drum to create friction and slow down the vehicle. They rely on hydraulic, pneumatic, or mechanical mechanisms to activate the braking action. | Disc brakes use brake pads that clamp onto a rotating disc (rotor) to generate friction and decelerate the vehicle. Hydraulic pressure is applied to the brake caliper to engage the brake pads against the rotor. |

| Heat Dissipation: | It sustains heat, that leading to brake fade under heavy use. | Disc brakes generally have better heat dissipation capabilities compared to drum brakes. The exposed design of disc brakes allows for efficient cooling, reducing the risk of brake fade during prolonged or heavy braking. |

| Braking Efficiency: | Comparatively generates less braking force so has less efficiency. | Disc brakes often provide more consistent and responsive braking performance compared to drum brakes. They generate higher clamping force and offer better modulation, resulting in shorter stopping distances. |

| Accessibility: | Drum brakes are often more accessible and easier to service due to their location behind the wheel assembly. This makes tasks like replacing brake shoes or inspecting components more convenient. | Generally require frequent maintenance due to exposed components. |

| Simplicity: | Drum brakes have a simpler design with fewer components, which can contribute to easier maintenance | It requires potentially more service costs compared to drum brakes. |

| Cost: | Drum brakes are generally more cost-effective compared to disc brakes. The simpler design and manufacturing process of drum brakes make them less expensive to produce and replace. | Often more expensive to manufacture. |

Pros and Cons of Drum Brakes compared to Disc Brakes:

Advantage of Drum Brakes

- Cost-effectiveness: Drum brakes are generally more affordable compared to disc brakes, making them a cost-effective choice, especially for budget-conscious consumers.

- Simplicity: Drum brakes have a straightforward design with fewer components, making them easier to manufacture, install, and maintain. They offer ease of service and repairs.

- Durability: Drum brakes are known for their durability and ability to withstand harsh operating conditions. Their robust construction makes them suitable for heavy-duty applications.

- Self-adjustment: Many drum brake systems feature a self-adjusting mechanism that automatically compensates for brake shoe wear, reducing the need for frequent manual adjustments.

Disadvantages of Drum Brakes

- Heat Dissipation: Drum brakes have limited heat dissipation capabilities compared to disc brakes. The enclosed design restricts airflow, making them more prone to overheating and potential brake fade under prolonged or heavy braking.

- Braking Performance: Drum brakes may provide less consistent and responsive braking performance compared to disc brakes. They can have longer stopping distances and reduced modulation.

- Maintenance: While drum brakes are generally easier to access and service, they require more frequent maintenance due to factors like self-adjustment mechanism wear and potential water-induced performance degradation.

- Weight and Bulkiness: Drum brakes are typically heavier and bulkier compared to disc brakes, which can contribute to increased unsprung weight and potentially impact overall vehicle handling and fuel efficiency.

It’s important to consider the specific requirements of the vehicle, including its intended use, performance needs, and personal preferences when choosing between drum brakes and disc brakes. Each system has its advantages and disadvantages, and the decision should be based on factors such as braking performance, maintenance needs, and cost considerations.

Troubleshooting and Inspection

Troubleshooting and Inspection of Drum Brakes:

- Brake Shoe Inspection: Regularly inspect the brake shoes for wear, damage, and proper adjustment. Look for signs of uneven wear, excessive wear on one side, or any loose or broken components. Ensure that the brake shoes have sufficient lining thickness and are within the specified measurement limits. Replace worn-out or damaged brake shoes promptly.

- Drum Inspection: Inspect the brake drum for signs of wear, scoring, or grooves on its inner surface. Measure the drum diameter and compare it to the manufacturer’s specifications to ensure it is within the acceptable range. If the drum is worn beyond the recommended limit or has severe damage, it may need to be resurfaced or replaced.

- Adjustments and Replacements: Maintain proper clearance between the brake shoes and drum by adjusting the brake shoe position or using the adjuster mechanism. Follow the manufacturer’s guidelines for adjusting the brakes to ensure optimal performance. If the brake shoes or other components are excessively worn, damaged, or not functioning correctly, replace them with new ones.

- Lubrication: Apply appropriate lubrication to moving parts such as the adjuster mechanism, backing plate contact points, and pivot points to ensure smooth operation and prevent excessive wear or sticking.

- Bleeding the Brake System: If you’ve recently replaced any brake components or opened the hydraulic system, bleed the brake system to remove any air bubbles and ensure proper brake fluid circulation.

- Testing and Road Performance: After performing any maintenance or adjustments, test the brakes on a safe road or suitable testing area. Gradually apply the brakes at different speeds to assess their performance, responsiveness, and balance. Ensure that the vehicle comes to a smooth and controlled stop without any abnormal noises or vibrations.

Regular inspection, proper maintenance, and timely replacement of worn-out or damaged components are essential for ensuring the optimal performance and safety of drum brakes. Following the manufacturer’s guidelines and seeking professional assistance if needed can help troubleshoot and address any issues effectively.

Conclusion

In conclusion, drum brakes play a significant role in the automotive system, providing reliable braking performance in various vehicles such as cars, motorcycles, and heavy-duty vehicles. They are cost-effective, simple to maintain, and durable, making them suitable for different operating conditions.

However, drum brakes have limitations, including limited heat dissipation, potential brake fade, and reduced performance in wet conditions. When compared to disc brakes, drum brakes may have longer stopping distances and require more frequent maintenance. Despite the prevalence of disc brakes, drum brakes continue to be relevant in certain applications. It is crucial to consider factors such as cost, braking performance, and vehicle requirements when choosing between drum brakes and disc brakes.

Overall, understanding the components, working principles, advantages, and limitations of drum brakes allows for informed decision-making, efficient maintenance, and safe operation of vehicles equipped with drum brake systems. Regular inspection, proper troubleshooting, and timely maintenance ensure optimal brake performance and contribute to overall vehicle safety.

FAQ

1. How to adjust drum brakes?

To adjust drum brakes, follow these general steps:

a. Remove the brake drum.

b. Locate the brake adjuster mechanism and rotate it to expand or retract the brake shoes.

c. Adjust the mechanism until the brake shoes are snug against the drum but still allow for slight movement.

d. Reinstall the brake drum and test the brakes for proper adjustment.

2. How long do drum brakes last?

The lifespan of drum brakes can vary depending on factors such as driving conditions, vehicle weight, and maintenance. On average, drum brakes can last between 30,000 to 70,000 miles. However, regular inspections and maintenance are crucial to ensure optimal performance and longevity.

3. How to measure brake drums?

To measure brake drums, you can follow these steps:

a. Remove the brake drum from the vehicle.

b. Use a brake drum measuring tool or a digital caliper to measure the diameter of the drum.

c. Compare the measured diameter to the manufacturer’s specifications to determine if the drum is within the acceptable range.

4. How to convert drum brakes to disc brakes?

Disc brake conversion:- Converting drum brakes to disc brakes involves several steps and may require specific conversion kits designed for your vehicle. It is recommended to consult a professional mechanic or refer to detailed conversion guides that provide step-by-step instructions tailored to your specific vehicle.

5. What is brake drum coupling?

Brake drum coupling refers to a mechanical coupling used to connect a drum brake assembly to another rotating component, such as a wheel or axle. It allows the transfer of braking force from the brake shoes to the drum, enabling the vehicle to slow down or stop.

6. Which is better, drum or disc brakes in scooters and bikes?

Disc brakes are generally considered more effective and provide better braking performance compared to drum brakes. They offer improved stopping power, enhanced modulation, and better heat dissipation, especially in demanding conditions. However, drum brakes can still be suitable for scooters and bikes, particularly in smaller and lighter applications, where cost-effectiveness and simplicity are priorities. The choice depends on factors such as the specific scooter or bike model, intended use, and personal preferences.