Table of Contents

ABSTRACT

Jig and fixture are the device required to hold and to locate the work pieces and to guide the tools. These devices are only economical in mass production with easy loading, unloading, holding and operational facilities and ensured interchangeability of machined workplace for quick assembly.

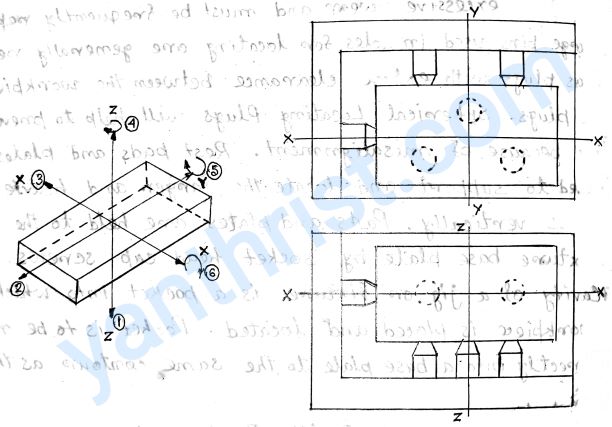

DEFINITION OF JIGS & FIXTURES

Jigs and Fixtures for at the devices require d for holding and locating the work pieces and guiding the tools these devices are only economical in mass and rapid production and insure interchangeability of finished products for achieving quick assembly and also reduce the time for free loading and unloading and setting the work piece.

JIGS

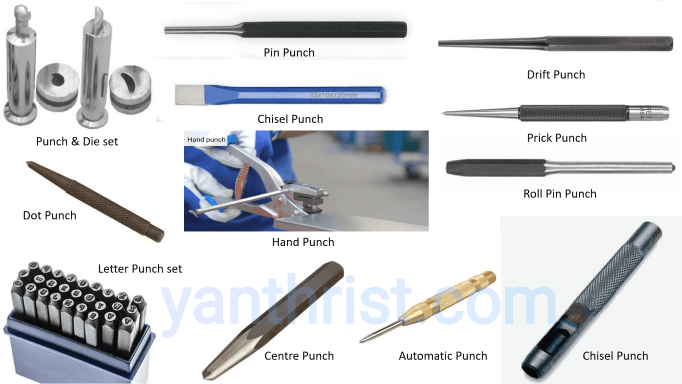

A jig is a device necessary for holding and locating the small workpieces rigidly on machine table and also for locating or guiding the tools during drilling or similar type of operations like reaming tapping.

FIXTURES

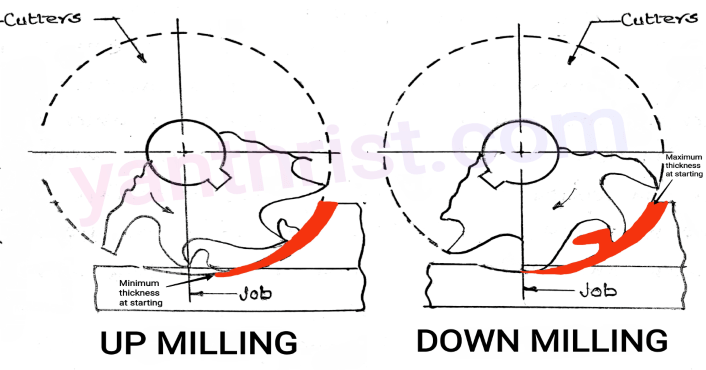

A fixture is a Device necessary for holding and locating the medium and heavier sized workpieces rigidly on machine table. The device will help for easy setting of workpieces relative to the tools but doesn’t guide the tools. Fixture is used to clamp, support and locate workpiece during inspection or in manufacturing operations like milling, planning, turning grinding etc.

DIFFERENCE BETWEEN JIGS AND FIXTURES

| POINTS | JIGS | FIXTURES |

| 1. Purpose | it holds and locate workpiece and also guides the tool | It holds and locate workpiece but doesn’t guide the tool. |

| 2. Construction | Jigs are smaller in size and lighter in construction. | Fixtures are larger and heavier in construction. |

| 3. Clamping | Due to rapid handling jigs are not clamped on machine generally. | Fixture must be clamped rigidly with machine bed or cross slide. |

| 4. Skill | Less skill required. | More skill required compared to jig |

| 5. Additional device | No additional device required to locate cutting tool. | Additional cutting tool required like blocks, gauge to accurately move the cutting tool with job. |

| 6. Operation | Jigs mostly used for drilling, reaming, boaring operation. | Fixture mostly used for Milling, shaping, planing operation. |

| 7. Design | Complex design. | Comparatively simple design. |

| 8. Fabrication time & cost | Less required. | More. |

| 9. Example | Diameter jig, plate jig, welded jig, channel jig etc. | Angle plates, V-Block etc. |

ADVANTAGES OF JIGS AND FIXTURES IN MASS PRODUCTION

- Jigs and fixtures are largely used for mass production of workpiece in industry at present time due to it’s following advantages,

- It can avoid measuring, marking setting etc. by locating the system.

- it minimize the setting time by fixing number of workpiece at a time and performing several operations in one setting.

- Operational accuracy increases as workpiece is rigidly fixed and located and tool is guided.

- It reduces the machining time by increasing depth of cut, feed and speed due to Its rigid clamping and guidance of tool.

- it increases interchangeability of final product as a result quicker assembly possible.

Factors to be consider before jig and fixture design

Before going jig and fixture design, Following are the Most important points to be remember-

- Easy and fast loading and unloading mechanism.

- Permitted clearance between Jig and Fixture body with the various sizes of casting or forging products.

- Cutter setting, indexing and guiding mechanism.

- Gateway for removal of scraps after cutting.

- Properly balanced to prevent frequent movement during operation.

- Quick ejection of heavy products mechanically.

- Safety requirements for product, operator and machine.

ALSO READ:- ELEMENTS OF JIG AND FIXTURE AND 3-2-1 PRINCIPAL OF LOCATION.

References:-

- MACHINE TOOLS(Workshop Technology) by R.N DUTTA

- Image source- https://www.indiamart.com/