Table of Contents

What is Brinell Hardness Tester

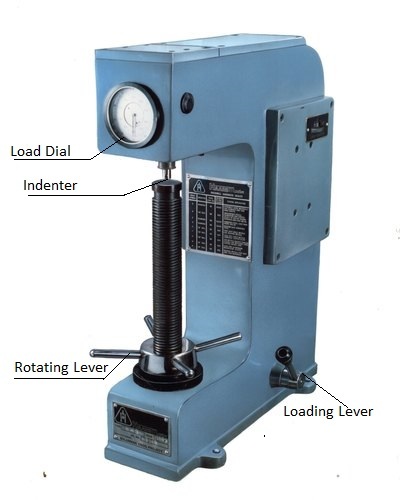

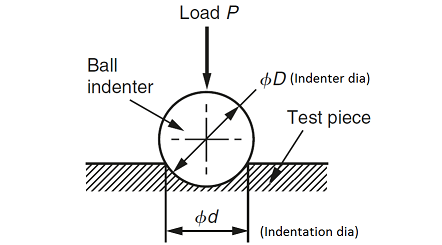

Brinell Hardness Tester is one of the most commonly used device to determine the hardness of a specimen. Hardness of a specimen is its characteristic property to resist scratch, indentation and penetration. Using Brinell Hardness Tester machine, a load is applied on the specimen to create an indentation through an indenter. The indenter is spherical in shape and is generally made up of Tungsten-Carbide. The various readings are then noted and the Brinell Hardness Number (BHN) formula is used to compute the result. The More the BHN, the harder is the specimen.

APPARATUS OF BRINELL HARDNESS TESTER

1. Brinell Hardness Tester Machine

2. Brinell Hardness Test Ball Indenter

3. Brinell Microscope

4. Test Specimen (Generally, Mild Steel Bar)

Procedure: How to Find Brinell Hardness

- The BHN Testing machine is made ready by fitting the indenter and setting the load as per specified manual.

- The specimen is placed on the platform and the rotating lever is rotated to lift the table so that the specimen presses against the indenter. The lever must be rotated until a minor load of 3kg gets applied against the specimen. The load reading is closely observed from the dial.

- Then, the load lever is pulled and the major load is applied.

- Once the pointer of the dial comes to rest, 15 seconds are allowed to elapse and then the load is released.

- The Brinell Microscope is used to observe the specimen closely and measure the indentation diameter.

Observations:

The following data are collected and noted to compute the Brinell Hardness Number (BHN).

1. Load applied by indenter=P (kgf)

2. Diameter of indenter ball= D (mm)

3. Diameter of indentation = d (mm); [To be noted every time after repeating the experiment to get more accurate results]

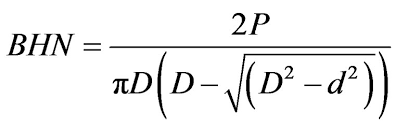

Formula for Calculating Brinell Hardness Number (BHN)

Brinell Hardness Calculator–

Here are the calculator to find out the BHN number easily if you have all following experimental data.

Load applied by indenter=P (kgf), Diameter of indenter ball= D (mm), Diameter of indentation = d (mm)

Note.- after putting input press ”CALCULATE”, then page will automatically refreshed and result will Display.

Sample Observation Table

Here we find out how to calculate Brinell hardness test. The observation table must be filled up as per the actual data found in the experiment. The BHN value has to be calculated for each experiment by the formula mentioned above.

| Sl. No. | Specimen Details | Dia. of Indenter (D) and Load Applied (P) | Indentation Dia (d) | BHN (As Calculated) |

| 01 | Mild Steel Bar | D=2.5 mm and P=187.5 kgf | 1.10 mm | 187.23 |

| 02 | -do- | -do- | 1.18 mm | 161.30 |

| 03 | -do- | -do- | 1.20 mm | 155.61 |

| 04 | -do- | -do- | 1.10 mm | 187.23 |

So, the Average BHN for the specimen = (187.23+161.30+155.61+187.23)/4 = 172.8425

YOU CAN ALSO READ CHARPY IMPACT TEST- Experiment to Determine the Toughness of a Material.

QUESTIONS RELATED TO BRINELL HARDNESS TESTING

1. Is Brinell Hardness Test destructive?

Yes, Brinell Hardness Test is a destructive test because the actual specimen gets indented (damaged) while performing the test. However, in many applications the indented specimen may also be used where stress concentration is not of much concern.

2. State advantages of hardness test using Brinell Hardness Tester.

Brinell Hardness Test gives more accurate results as it covers a larger area of indentation as compared to other hardness testing methods such as Vickers’s Hardness Test.

3. State disadvantages of hardness test using Brinell Hardness Tester.

The biggest disadvantage of BHN test is that the reading of the indentation diameter is taken manually by observation under microscope. This measurement might not be very accurate and can cause the results to vary from the actual value.

4. What combination of load and indenter is used generally?

For steel and cast iron, ball indenter diameter of 2.5 mm is used and load of 187.5 kgf is preferred.

Whereas, for Copper and Aluminum alloys, indenter of 5 mm diameter and load of 250 kgf is used.

5. What is the difference between Brinell and Rockwell hardness

- Brinell hardness tester used for rough surface like Forged, casted metal while Rockwell used for smooth surface like grinded, finished surface metal

- Brinell tester is much more time consuming than Rockwell machine.

- Brinell used for larger size metal while Rockwell used for smaller material.

- Rockwell hardness testing is more error free.